In the ever-evolving landscape of manufacturing, the Aluminium Extrusion Profile has emerged as a pivotal component that significantly enhances operational efficiency. According to a report by Grand View Research, the global aluminium extrusion market is projected to reach USD 118.9 billion by 2025, driven by the increasing demand for lightweight materials across various industries, including automotive, construction, and electronics. The versatility of aluminium extrusion profiles allows for seamless integration into diverse applications, from structural components to intricate designs, thus boosting productivity and minimizing waste. With advancements in extrusion technology and an emphasis on sustainability, businesses are increasingly turning to these profiles not just for their functional benefits but also for their role in reducing carbon footprints and promoting eco-friendly practices. This blog will delve into the seven best aluminium extrusion profiles that promise to optimize efficiency in 2023, underscoring the importance of selecting the right profile for specific industrial needs.

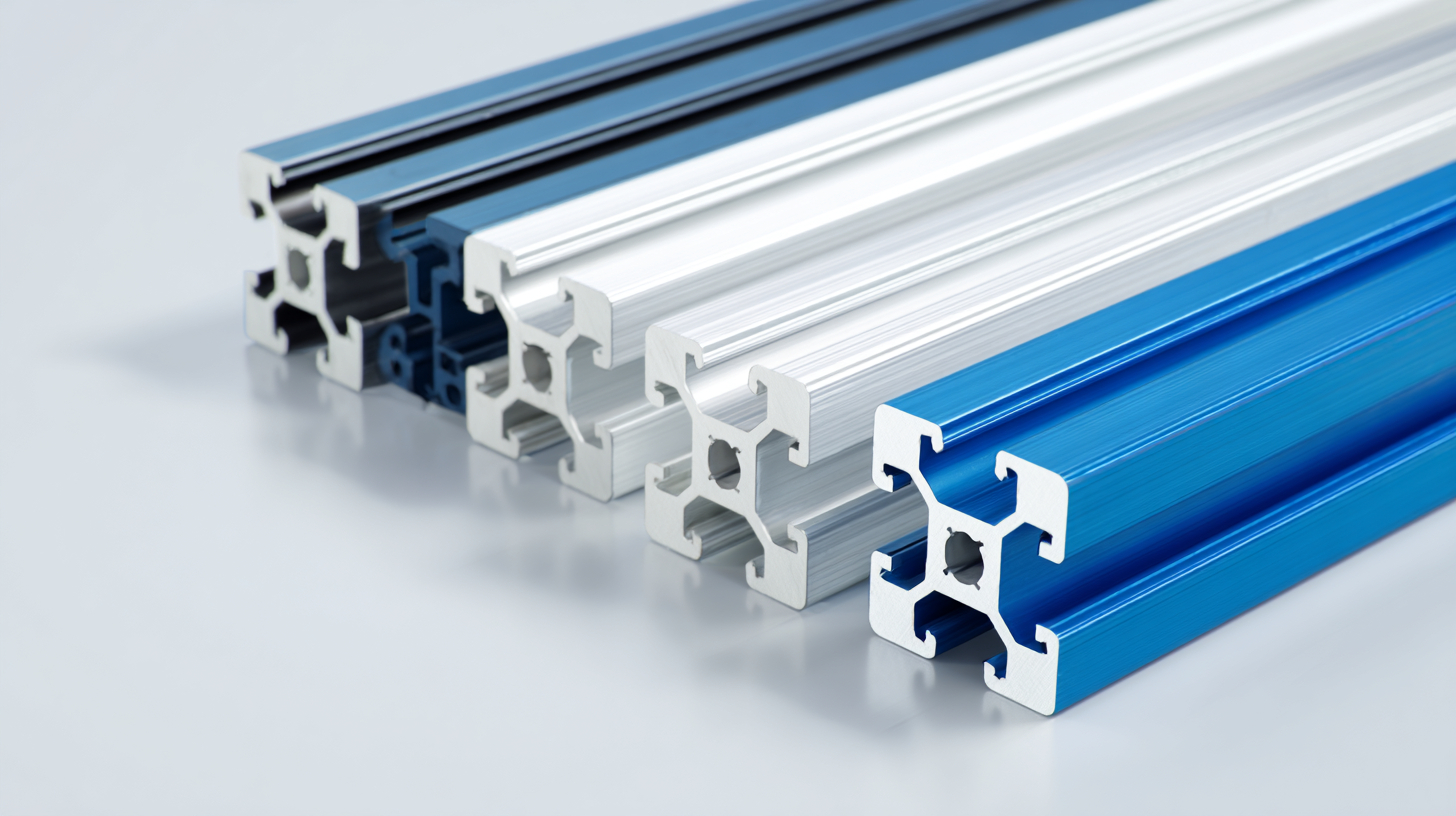

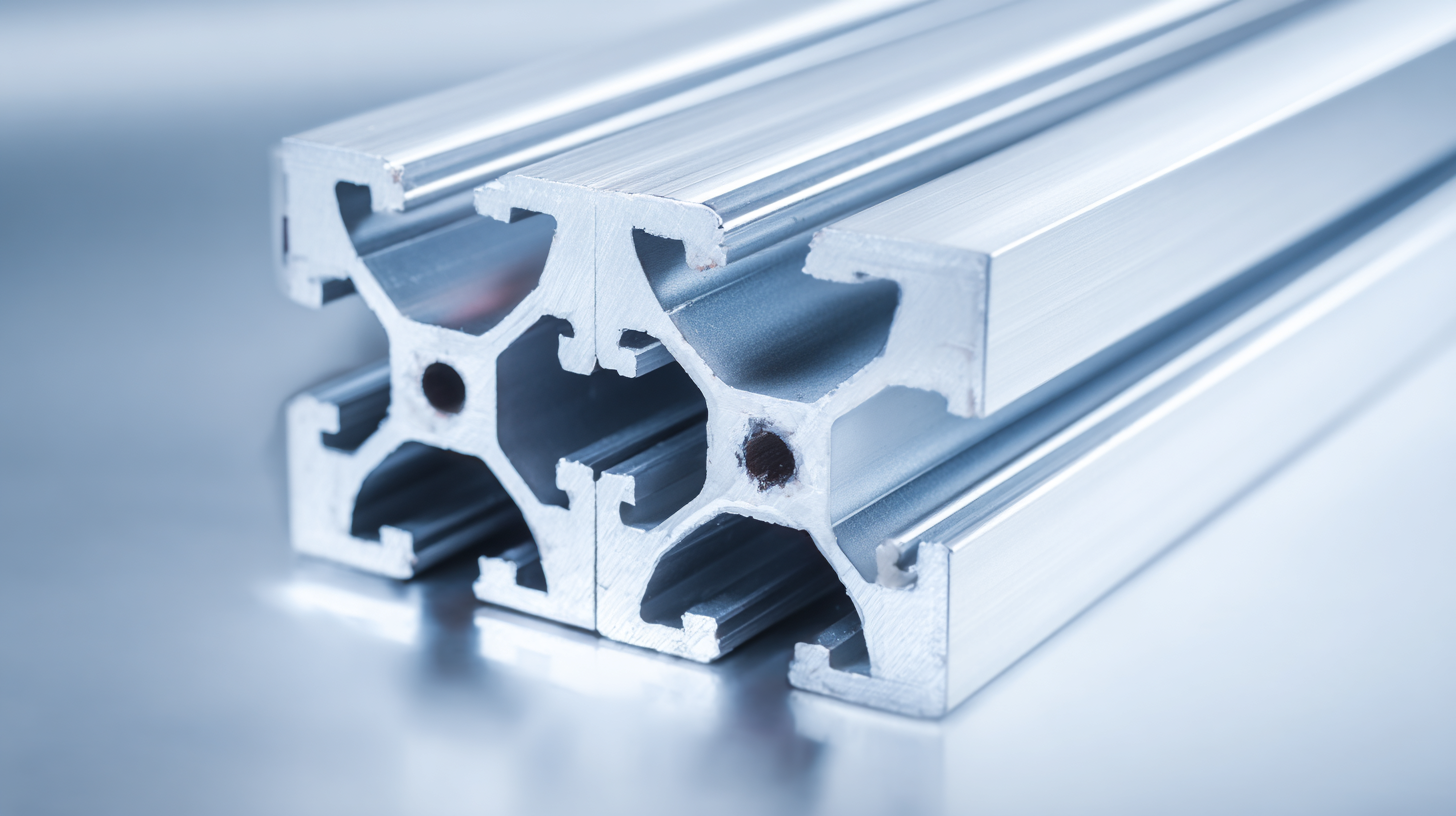

Aluminium extrusion profiles have gained significant attention due to their versatility and efficiency across various industries, including construction, automotive, and manufacturing. According to a recent report by the Aluminium Extruders Council, the global market for aluminium extrusions is projected to grow by 5.6% annually, driven by rising demand for lightweight yet durable materials. These profiles allow for precise customization, enabling manufacturers to create complex shapes that can enhance structural integrity while reducing weight.

Aluminium extrusion profiles have gained significant attention due to their versatility and efficiency across various industries, including construction, automotive, and manufacturing. According to a recent report by the Aluminium Extruders Council, the global market for aluminium extrusions is projected to grow by 5.6% annually, driven by rising demand for lightweight yet durable materials. These profiles allow for precise customization, enabling manufacturers to create complex shapes that can enhance structural integrity while reducing weight.

One of the key benefits of aluminium extrusion profiles is their energy efficiency. The use of aluminium can lead to substantial energy savings during both the production and end-use phases. For instance, a study by the International Aluminium Institute indicates that substituting traditional materials with aluminium can lead to energy savings of up to 30% in building applications. Additionally, aluminium's excellent thermal conductivity makes it an ideal choice for applications requiring heat exchange, thus further improving overall efficiency. As industries increasingly seek sustainable solutions, the role of aluminium extrusion profiles will undoubtedly expand, solidifying their importance in innovative design and construction methodologies.

Aluminium extrusion profiles play a pivotal role in enhancing operational efficiency across various industries. According to the latest report by the Aluminium Association, the global demand for aluminium extrusions is projected to reach 18 million metric tons by 2025, driven by their versatility and lightweight properties. In 2023, several profiles have emerged as frontrunners in maximizing productivity, particularly in sectors like construction, automotive, and electronics.

One notable example is the modular aluminium extrusion profile, which supports customizable designs, enabling companies to optimize their manufacturing processes and reduce waste. A study by Grand View Research highlighted that modular systems can improve assembly time by up to 30%, significantly impacting overall operational efficiency. Additionally, the use of thermal breaks in aluminium profiles has been shown to reduce energy consumption by approximately 20%, making buildings more sustainable and cost-effective. These advancements underscore the critical importance of selecting the right aluminium extrusion profiles to drive productivity and enhance performance in contemporary industrial applications.

| Profile Type | Key Features | Applications | Efficiency Gains |

|---|---|---|---|

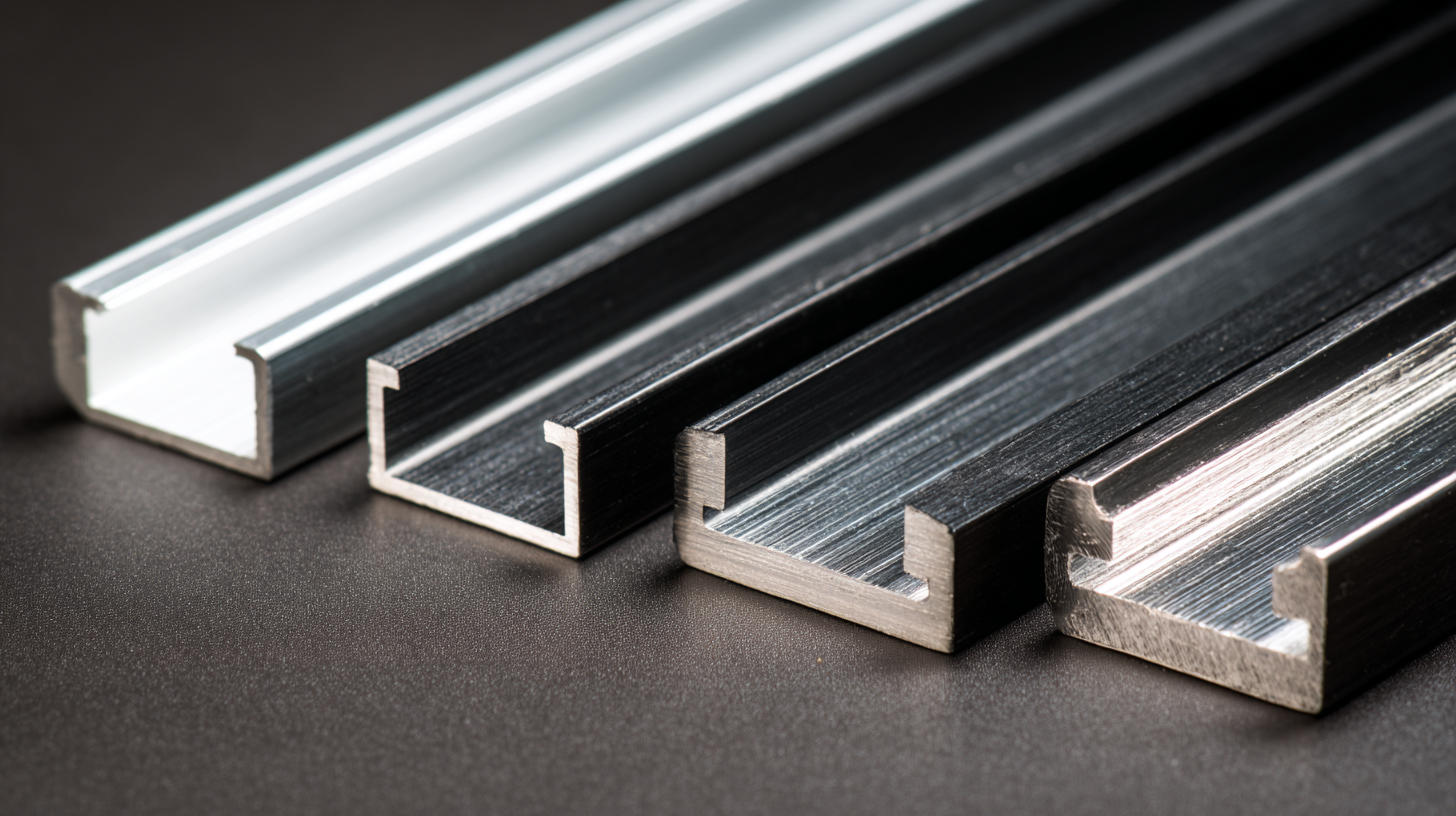

| T-Slot Extrusions | Versatile connection points, easy assembly | Frameworks, machine guards | Improved reusability |

| L-Shape Extrusions | Strong corners, aesthetic appeal | Support brackets, displays | Enhanced structural integrity |

| U-Shape Extrusions | High load capacity, stability | Railings, trays | Maximized space utilization |

| Box Section Extrusions | Uniform strength, rigidity | Frames, enclosures | Increased load-bearing capability |

| Corner Extrusions | Easy installation, effective sealing | Windows, doors | Better thermal insulation |

| Channel Extrusions | Holds components securely | Conveyors, supports | Streamlined production flow |

| Flat Bar Extrusions | Various thickness options | Bracing, joinery | Cost-effective solutions |

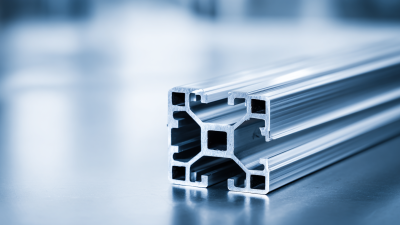

When selecting aluminium extrusion profiles for enhanced efficiency, it's vital to focus on key features that can significantly optimize your production processes. One crucial aspect is the alloy's strength-to-weight ratio; profiles made from high-quality alloys like 6061 or 6063 can offer excellent mechanical properties while remaining lightweight. According to the Aluminium Association, using the right alloy can improve structural integrity by up to 20%, enhancing durability in various applications.

Another important factor is the surface finish. Profiles with anodized or powder-coated finishes not only provide enhanced corrosion resistance but also contribute to a better aesthetic appeal. The American Institute of Architects notes that the right finish can increase your product's lifespan by 30% or more, making it a worthwhile investment for manufacturers looking to ensure long-term use.

Tip: When choosing extrusion profiles, consider the thermal conductivity, as some alloys can efficiently dissipate heat. This is particularly beneficial in thermal management applications, where maintaining optimal temperatures is crucial. Additionally, always check the profile's compatibility with your existing production equipment to avoid unforeseen delays and costs.

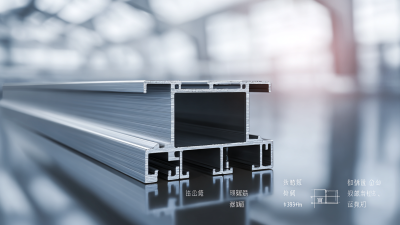

Aluminium extrusion is a versatile manufacturing process widely adopted across various industries due to its unique properties and capabilities. In the construction sector, aluminium extrusion profiles are crucial for creating durable and lightweight window frames, door frames, and structural supports, ensuring both strength and aesthetic appeal in buildings. The customizable nature of these profiles allows architects to design innovative facades and energy-efficient systems that contribute to modern architectural trends.

In the automotive industry, aluminium extrusions are increasingly used to create lightweight components, improving fuel efficiency and reducing carbon emissions. From chassis to interior elements, these profiles provide strength without the excessive weight of traditional materials. Additionally, the electronics sector utilizes aluminium extrusion for heat sinks and casings, benefiting from the metal's excellent thermal conductivity and corrosion resistance. These applications highlight the importance of aluminium extrusion in driving efficiency and sustainability across multiple industries in 2023.

When selecting the right aluminium extrusion profile for your specific needs, it is essential to consider a few key factors that can greatly enhance efficiency. Firstly, assess the application of the profile: whether it will be used for structural support, heat dissipation, or aesthetic purposes. Understanding the primary function will help narrow down the options. Additionally, consider the weight and strength requirements; thinner, lighter profiles may suffice for less demanding applications, while more robust profiles are necessary for heavy-duty uses.

Another critical aspect is the surface treatment of the aluminium. Different finishes, such as anodizing or powder coating, can enhance durability and corrosion resistance, making them ideal for outdoor or industrial environments. Furthermore, take into account the manufacturing process; profiles with more intricate designs may require advanced fabrication technologies, which could impact production time and costs. By carefully evaluating these criteria, you can select an aluminium extrusion profile that not only meets your immediate needs but also contributes to increased operational efficiency.