In the dynamic landscape of manufacturing, sourcing high-quality Extrusion Aluminum Profiles has become a critical factor for competitive advantage. According to a recent report by the Aluminum Association, the global demand for aluminum profiles is projected to exceed 35 million metric tons by 2025, driven by their versatile applications across various industries such as automotive, construction, and aerospace. This increase in demand underscores the importance of adhering to stringent industry manufacturing standards, which ensure product performance and safety. With numerous suppliers available worldwide, understanding how to effectively evaluate and select the best extrusion aluminum profiles is paramount for businesses aiming to optimize their supply chains and enhance product quality. In this ultimate checklist, we will explore the essential considerations and best practices for sourcing these critical materials globally, ensuring that your procurement strategy remains robust and effective.

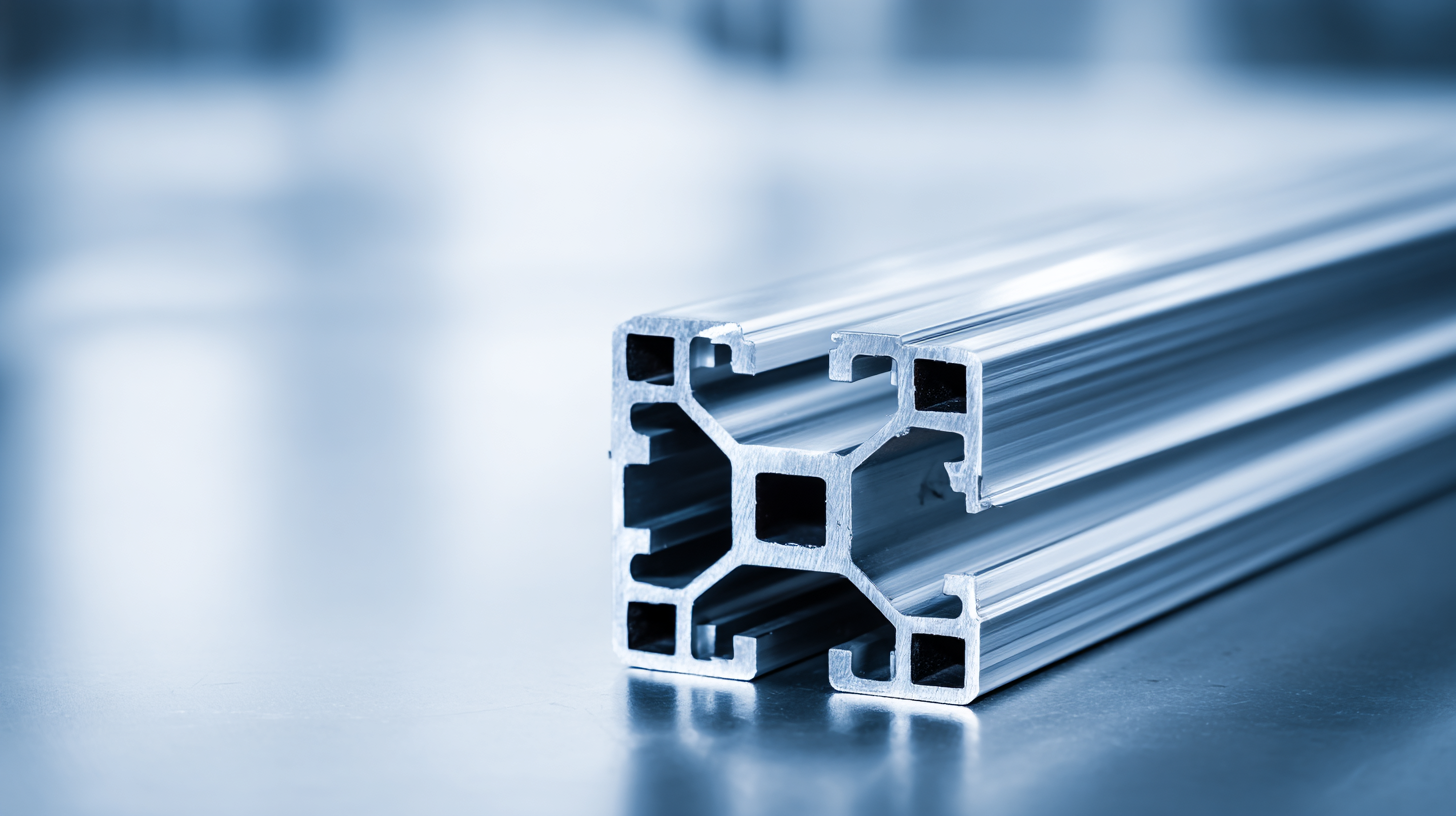

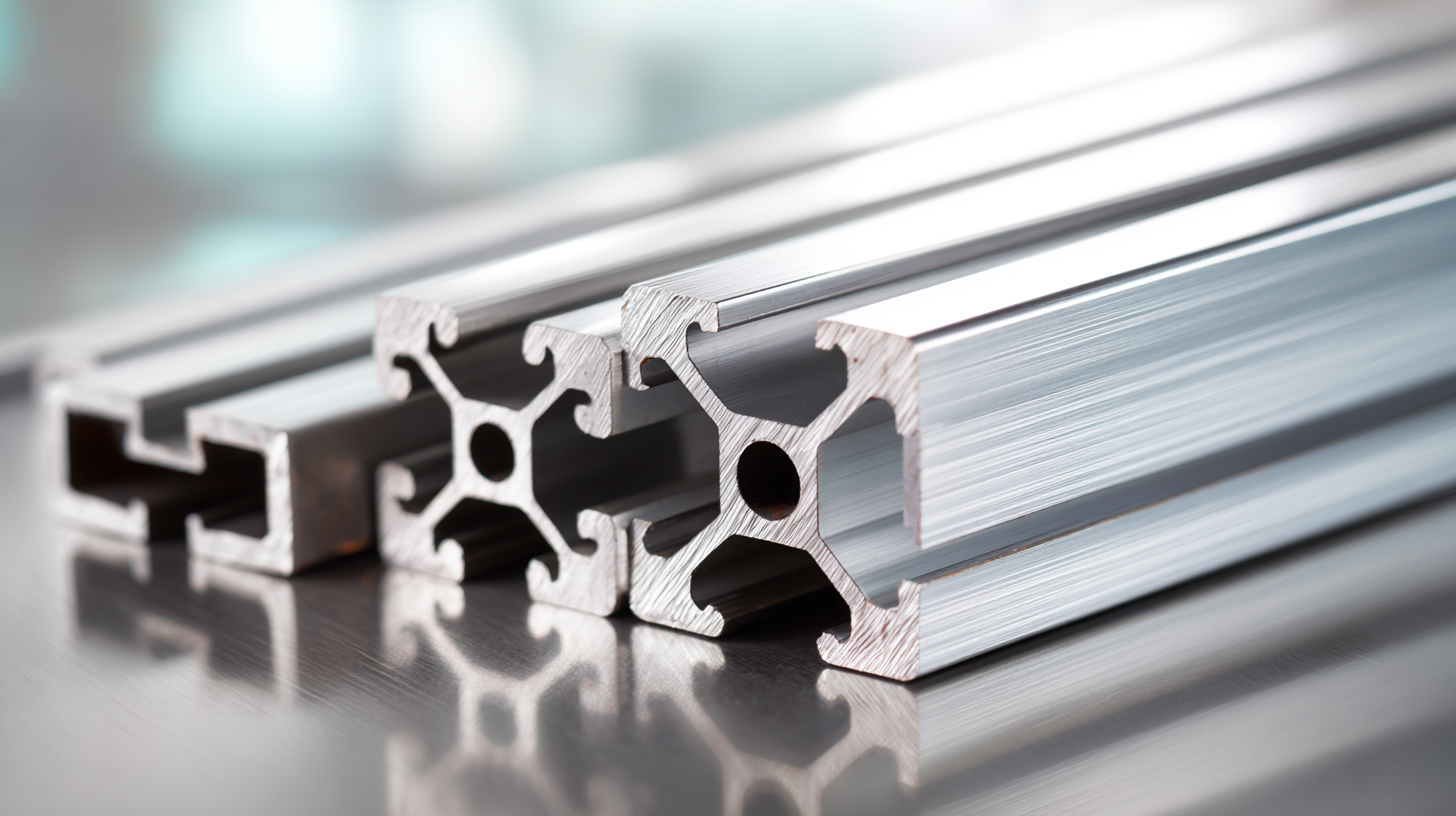

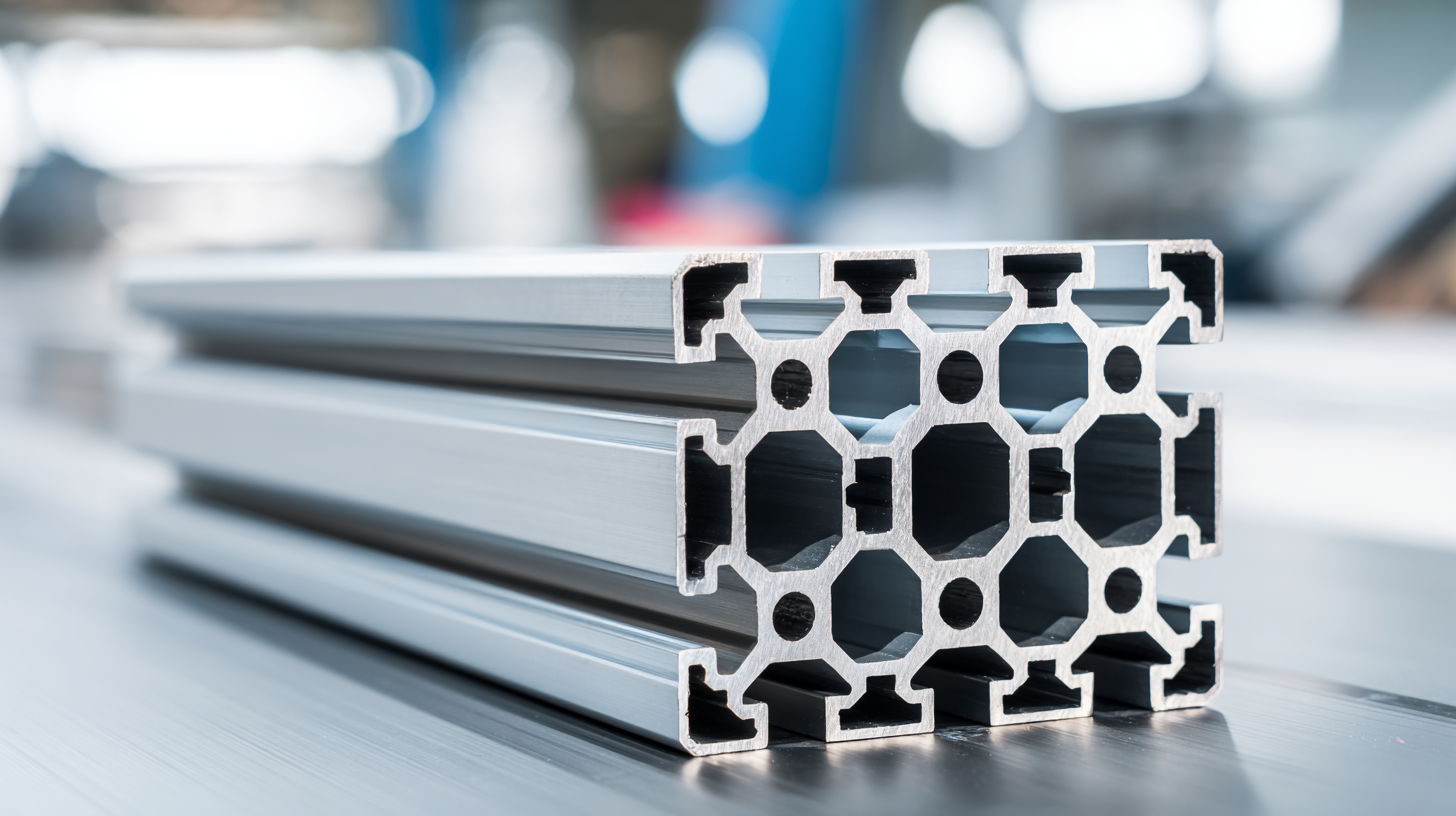

When sourcing extrusion aluminum profiles, it’s essential to first identify your specific needs. There are various types of profiles to consider, each tailored for unique applications. For example, architectural profiles are designed for structural support in buildings, providing aesthetic appeal and durability. They often come in shapes such as angles, channels, and T-profiles, making them versatile for construction and design projects.

Another crucial category is industrial profiles, which are utilized in manufacturing and machinery. These profiles are engineered for strength and reliability, often seen in equipment frames and assembly lines. Furthermore, specialty profiles, such as those used in automotive or aerospace applications, may require specific alloys or customized designs to meet stringent performance standards. By understanding the different categories and typical uses of extrusion aluminum profiles, you can make informed decisions that align with your project requirements and ensure optimal functionality and efficiency.

In the quest for sourcing the best extrusion aluminum profiles globally, evaluating the quality of manufacturers through key certifications and standards is crucial. Certifications such as ISO 9001, which emphasizes a strong quality management system, are essential as they ensure that manufacturers consistently meet customer and regulatory requirements. According to a report by the Aluminum Association, about 80% of top-tier aluminum suppliers hold ISO certifications, showcasing their commitment to quality and operational excellence.

Additionally, adherence to industry-specific standards such as ASTM B221 for aluminum extrusions guarantees that products meet the necessary mechanical properties and specifications. A study from the International Aluminum Institute indicates that aluminum profiles meeting these standards exhibit a 30% reduction in defects compared to those that do not. By prioritizing suppliers with recognized certifications and adherence to established standards, companies can significantly enhance their supply chain reliability and product performance in various applications, from construction to automotive industries.

This chart displays the evaluation of various key certifications and standards for extrusion aluminum profile manufacturers around the world. The data illustrates the percentage of manufacturers meeting specific quality certifications, which is crucial for ensuring high standards in aluminum profile production.

When sourcing extrusion aluminum profiles globally, understanding pricing structures is crucial for achieving value for money. Recent industry reports indicate that the global aluminum extrusion market is projected to reach $123.5 billion by 2026, growing at a CAGR of 5.8% from 2022. This growth is driven by increasing demand in sectors such as automotive, construction, and electronics, where lightweight and durable materials are essential. A comprehensive cost analysis reveals that factors such as material costs, processing techniques, and logistics significantly influence pricing.

For instance, the average cost of aluminum alloy has fluctuated between $2,200 and $2,500 per metric ton, depending on market conditions. Additionally, extrusion techniques like direct and indirect extrusion can add varying costs—direct extrusion typically being less expensive due to lower energy consumption. Important to note, the total landed cost also incorporates shipping, tariffs, and handling fees, which can vary significantly by region. Understanding these components allows businesses to make informed sourcing decisions that optimize overall expenditure and maximize value derived from their suppliers.

For instance, the average cost of aluminum alloy has fluctuated between $2,200 and $2,500 per metric ton, depending on market conditions. Additionally, extrusion techniques like direct and indirect extrusion can add varying costs—direct extrusion typically being less expensive due to lower energy consumption. Important to note, the total landed cost also incorporates shipping, tariffs, and handling fees, which can vary significantly by region. Understanding these components allows businesses to make informed sourcing decisions that optimize overall expenditure and maximize value derived from their suppliers.

When sourcing extrusion aluminum profiles, assessing supplier reliability is paramount. The reputation and experience of manufacturers can significantly affect the quality and performance of the products. According to a report by the Aluminum Association, over 80% of buyers prioritize manufacturer reputation as a key factor in their purchasing decisions. This highlights the importance of thorough background checks on potential suppliers. Key indicators of a reliable supplier include years of operation, client testimonials, and certifications such as ISO 9001, which ensures quality management systems.

Moreover, industry data suggests that suppliers with a solid reputation tend to maintain the lowest defect rates and the highest on-time delivery percentages, often exceeding 95%. Engaging with industry forums and reviews can further reveal insights into supplier performance. A manufacturer's experience in specific sectors, such as automotive or construction, can also provide context regarding their capabilities in delivering tailored solutions. As businesses expand their sourcing strategies globally, a robust evaluation process based on these factors will ensure the selection of reliable manufacturers, ultimately leading to better product quality and project success.

When embarking on a journey to source the best extrusion aluminum profiles globally, businesses must adopt comprehensive and effective global sourcing strategies. A recent report highlights that the demand for sustainable materials is on the rise, propelled by a growing emphasis on eco-friendly manufacturing practices. With sustainable materials like recycled aluminum becoming scarcer, it is imperative for companies to establish reliable relationships with top suppliers who prioritize sustainability in their operations.

Furthermore, the geopolitical landscape plays a significant role in sourcing decisions. Ukraine's strategic position as a potential supplier of critical raw materials, including rare earth metals, positions it as a pivotal player in the aluminum supply chain. Companies looking to secure their supply chains must consider not only the quality of the aluminum profiles but also the availability of sustainable sources and the geopolitical factors that could influence supply stability. By leveraging data from industry analyses, which indicate a forecasted 6% annual growth in the global aluminum profile market through 2030, businesses can better navigate the complexities of sourcing while aligning with sustainable practices.