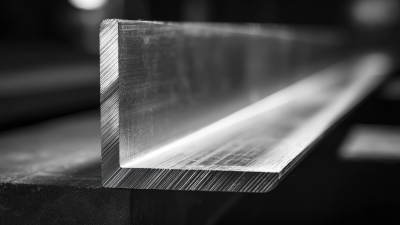

In the construction industry, the choice of materials directly impacts project efficiency, safety, and cost-effectiveness. Among the various options available, Aluminium Scaffold Tube has emerged as a superior choice for scaffolding needs. According to a report by Research and Markets, the global scaffolding market is projected to reach $65.6 billion by 2026, driven largely by the rapid expansion of the construction sector and the increasing focus on safety regulations. Aluminium Scaffold Tube, known for its lightweight yet durable properties, allows for easy assembly and disassembly, reducing labor costs and time on site. Furthermore, with the increasing emphasis on sustainable building practices, Aluminium's recyclable nature aligns with contemporary environmental standards, making it a compelling option for modern construction projects. Adopting Aluminium Scaffold Tube not only enhances operational efficiency but also contributes to a safer working environment, thereby positioning construction firms for success in a competitive landscape.

Aluminium scaffold tubes have increasingly gained popularity in the construction industry due to their numerous advantages over traditional steel options. One of the primary benefits is their lightweight nature, which can lead to substantial cost savings in transportation and handling. According to a report by the Construction Industry Research and Information Association (CIRIA), switching to aluminium scaffold tubes can reduce manual handling injuries by up to 30%, emphasizing the importance of safety on construction sites.

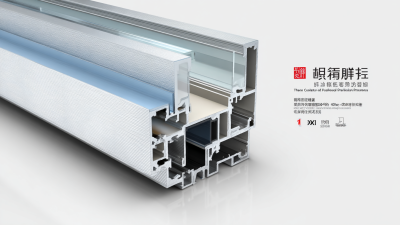

Another significant advantage is the corrosion resistance of aluminium. Unlike steel, which may rust and require regular maintenance, aluminium remains robust over time without significant deterioration. The American Institute of Steel Construction (AISC) highlights that aluminium's durability can extend the service life of scaffolding systems, making it a more economical choice over the long term despite the initial investment.

Tips: When selecting scaffold materials, consider the weight limits and specific project conditions. Regularly inspect your scaffolding system for any signs of wear, especially in environments prone to moisture. Additionally, proper training for workers handling aluminium scaffolds can further reduce the risk of accidents and enhance operational efficiency.

When considering scaffolding options for your construction projects, the strength-to-weight ratio is a crucial factor that cannot be overlooked. Aluminium scaffolding offers a significant advantage over steel due to its lightweight nature, which enhances ease of transportation and assembly on-site. Aluminium's strength-to-weight ratio makes it ideal for projects where mobility and efficiency are essential, allowing workers to handle and reposition scaffolding with greater ease compared to the heavier steel alternatives.

Tips: When selecting scaffolding, consider how ease of installation can impact project timelines. Additionally, evaluate the environmental conditions of the project site—aluminium’s corrosion resistance can be particularly beneficial in areas with high moisture.

Furthermore, advancements in material technology, such as the ongoing developments in lightweight composite structures, are reshaping the scaffolding landscape. With enhanced manufacturing processes, the integration of modern materials maintains structural integrity while minimizing weight. This evolution not only supports construction workers but also aligns with the growing demand for sustainable building practices. In an era where efficiency and sustainability are paramount, aluminium scaffolding stands out as a smart choice for contemporary construction projects.

When it comes to construction projects, cost efficiency is a primary concern for many contractors.

Aluminium scaffold tubes offer exceptional long-term savings that can significantly enhance a project's budget management.

Compared to traditional materials like steel, aluminium is lighter and easier to handle, which can reduce labor costs and increase productivity on-site.

The ease of setup and takedown means that projects can progress faster, allowing for more efficient use of time and resources.

Aluminium scaffold tubes offer exceptional long-term savings that can significantly enhance a project's budget management.

Compared to traditional materials like steel, aluminium is lighter and easier to handle, which can reduce labor costs and increase productivity on-site.

The ease of setup and takedown means that projects can progress faster, allowing for more efficient use of time and resources.

Moreover, aluminium's durability and resistance to corrosion mean that these scaffold tubes are a wise investment for the future.

Unlike steel scaffolding, which can rust and require frequent replacement, aluminium maintains its structural integrity over time.

This reduces the need for ongoing maintenance costs and replacements, further contributing to overall savings.

In heavy-duty applications, the lower weight of aluminium translates to savings in transportation costs while allowing for more flexible configurations on-site,

making it a versatile choice that stands the test of time.

By choosing aluminium scaffold tubes, construction projects can achieve both safety and economic efficiency.

When selecting scaffolding materials for construction projects, it's essential to consider industry standards and safety ratings. Aluminium scaffolding systems have gained recognition for their high safety profile, being lightweight yet robust enough to support significant loads. According to the International Organization for Standardization (ISO), aluminium scaffolding meets ISO aluminum scaffolding standard 4425, which emphasizes strength, stability, and safety in construction environments. This adherence to standards makes aluminium a preferred choice among construction professionals.

Tip: Always verify that the aluminium scaffolding systems you choose are certified by recognized organizations, ensuring they meet the required safety ratings for your specific construction project.

Moreover, the Occupational Safety and Health Administration (OSHA) highlights that compliant scaffolding systems drastically reduce workplace injuries. In particular, aluminium scaffolding minimizes the risk of falls, which account for nearly 40% of construction-related fatalities. By using aluminium scaffolding, companies can improve their safety ratings while adhering to industry regulations.

Tip: Regularly inspect your scaffolding for wear and tear, particularly the joints and connections. Maintaining your equipment ensures safety and prolongs its lifespan, enhancing overall project efficiency.

| Dimension | Specification | Safety Rating | Weight Capacity (kg) |

|---|---|---|---|

| 48.3mm Diameter | EN 74-1 | Class B | 250 |

| 60.3mm Diameter | EN 74-2 | Class A | 300 |

| 76.1mm Diameter | AS/NZS 1577 | Class C | 350 |

| 90mm Diameter | OSHA Standards | Class D | 400 |

The environmental impact of using aluminium scaffold tubes in construction is significant and largely positive. Aluminium is a highly recyclable material, which means that at the end of its life cycle, scaffolding can be repurposed rather than discarded in landfills. This recycling process requires considerably less energy compared to the production of new aluminium, ultimately reducing greenhouse gas emissions. By choosing aluminium, construction projects can contribute to a circular economy, minimizing waste and promoting sustainable practices.

Additionally, aluminium scaffold tubes are lightweight yet durable, which allows for easier transportation and handling on-site. This reduction in weight not only makes the construction process more efficient but also lessens the environmental footprint associated with fuel consumption during transport. Moreover, the longevity of aluminium scaffolding means that it needs to be replaced less frequently, further conserving resources and energy used in manufacturing. In summary, the decision to utilize aluminium scaffold tubes aligns with the growing need for sustainable construction methods, offering both ecological and practical benefits.