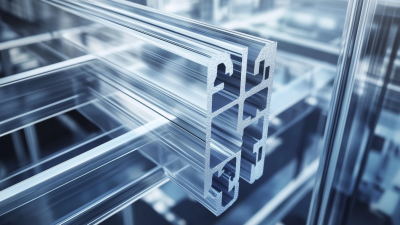

In recent years, the construction industry has increasingly turned to the use of Thermal Break Aluminium Profiles due to their superior insulation properties and energy efficiency benefits. According to a report by the Global Aluminium Association, buildings account for approximately 40% of global energy consumption, and by incorporating thermal break technology, energy loss can be reduced by up to 30%. This has significant implications not only for reducing utility costs but also for meeting stringent energy codes and sustainability goals. As architects and builders strive to create more energy-efficient structures, selecting the appropriate Thermal Break Aluminium Profiles becomes critical. Factors such as thermal performance, structural integrity, and aesthetic compatibility must be carefully considered to ensure the success of any project. This guide aims to equip you with essential insights and practical tips to navigate this selection process effectively.

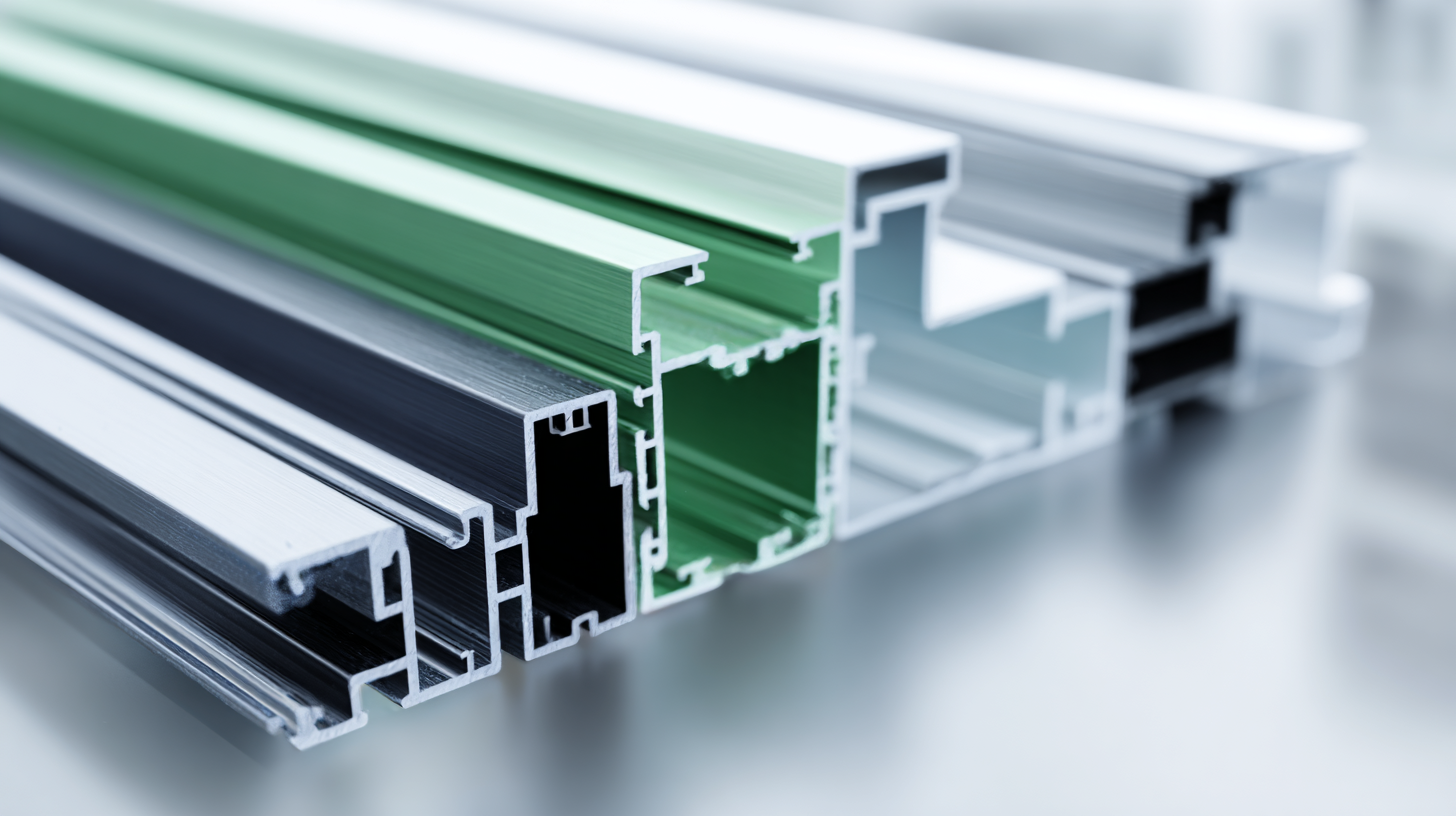

When selecting thermal break aluminium profiles for construction projects, several key factors must be taken into account to ensure energy efficiency and enhance the building's performance. The material’s thermal performance plays a crucial role, as it directly affects the overall energy consumption of the building. High-performance windows and doors can significantly improve insulation, thereby reducing heating and cooling costs. Evaluating the thermal transmittance values and understanding the insulation capabilities of various profiles is essential for making an informed decision.

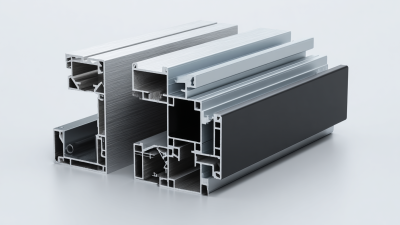

Moreover, sustainability is increasingly becoming a priority in construction. Emerging trends showcase the importance of innovative production technologies that minimize environmental impact while enhancing the durability of materials. Choosing profiles that are made from sustainable sources or that offer recyclability can contribute to the building's overall sustainability goals. In addition to performance, factors such as aesthetic appeal, compatibility with other materials, and compliance with local building codes should also be considered to ensure a well-rounded selection that meets the project's specific needs.

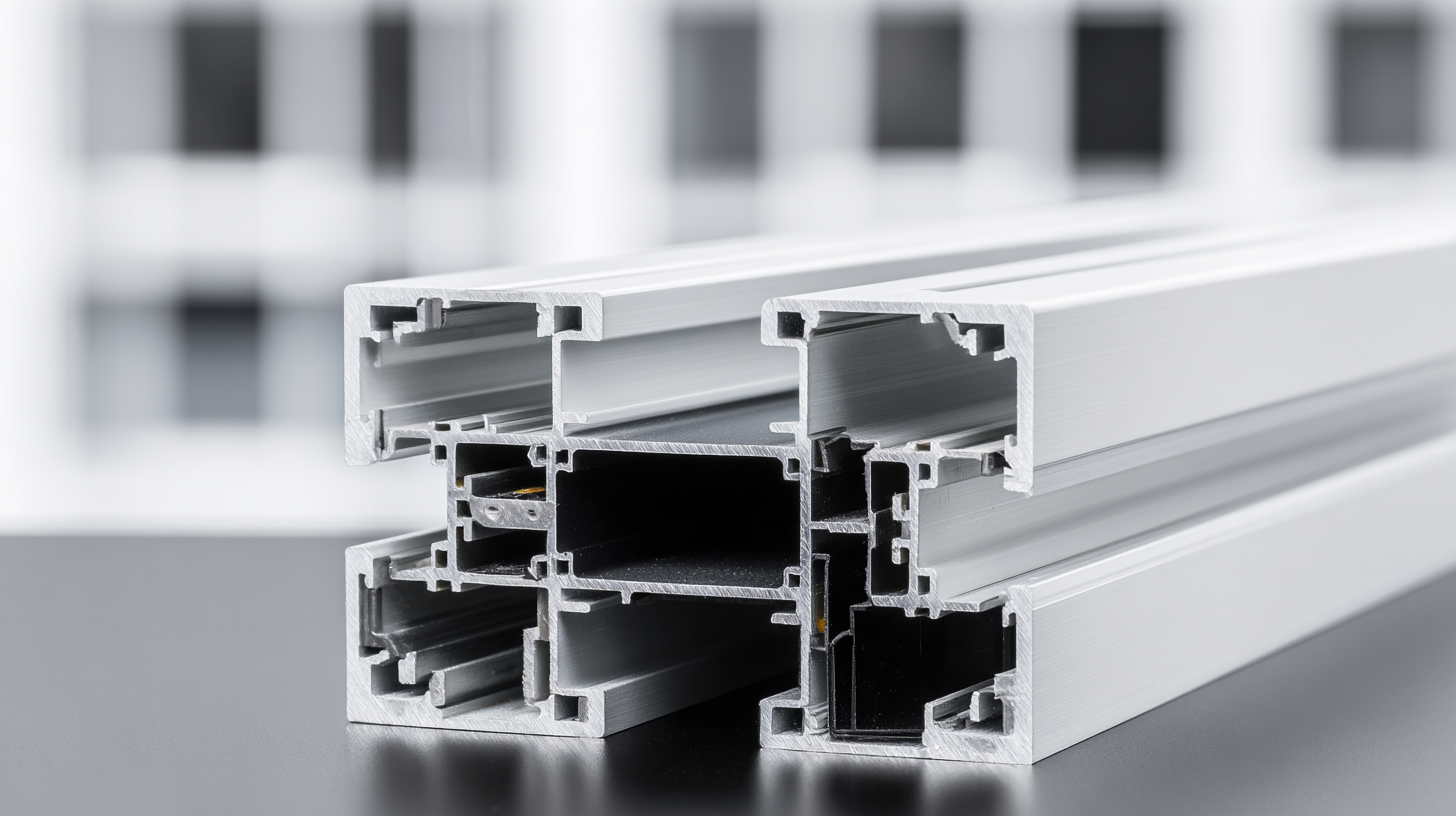

Thermal breaks are crucial in enhancing energy efficiency and improving insulation performance in buildings. By creating a separation between the exterior and interior sides of aluminium profiles, they minimize the transfer of heat, cold, and moisture. This is especially beneficial in regions with extreme temperatures, as it helps to maintain a comfortable indoor climate while reducing the reliance on heating and cooling systems. Consequently, the incorporation of thermal breaks can lead to significant energy savings and lower utility bills over the lifespan of a building.

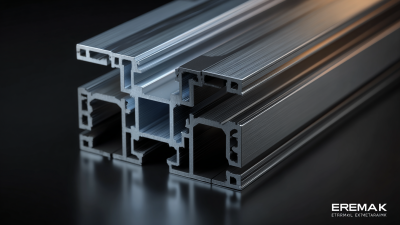

When selecting thermal break aluminium profiles for a project, it’s essential to consider the materials used in the thermal break itself. Common options include polyurethane or polyamide, which offer varying degrees of insulation performance. The effectiveness of these materials can significantly impact overall energy efficiency. Additionally, the design and thickness of the thermal break should be evaluated, as they influence how well the profiles perform in real-world conditions. Understanding these factors will allow project managers and architects to make informed decisions that enhance the building's overall sustainability and energy performance.

When selecting thermal break aluminium profiles for a project, it is crucial to consider industry standards and certifications that ensure both performance and quality. Key certifications to look for include the National Fenestration Rating Council (NFRC) certification, which provides reliable energy performance ratings for windows and doors, and the American Architectural Manufacturers Association (AAMA) certifications that confirm product performance against stringent durability and performance tests. Compliance with these standards can significantly influence the energy efficiency, insulation properties, and overall lifespan of the aluminium profiles used in construction.

With the evolving market dynamics, especially evident in regions like Saudi Arabia, demand for high-quality thermal break aluminium profiles is on the rise, driven largely by increasing construction activities and a heightened focus on energy efficiency. According to recent industry reports, the aluminium windows and doors market in Saudi Arabia is projected to grow significantly, fueled by advancements in technology and design.

Notably, profiles that adhere to international standards not only enhance the sustainability of buildings but also contribute to long-term cost-effectiveness by reducing energy consumption. Thus, understanding the relevant certifications and choosing profiles that meet these benchmarks is essential for ensuring successful project outcomes.

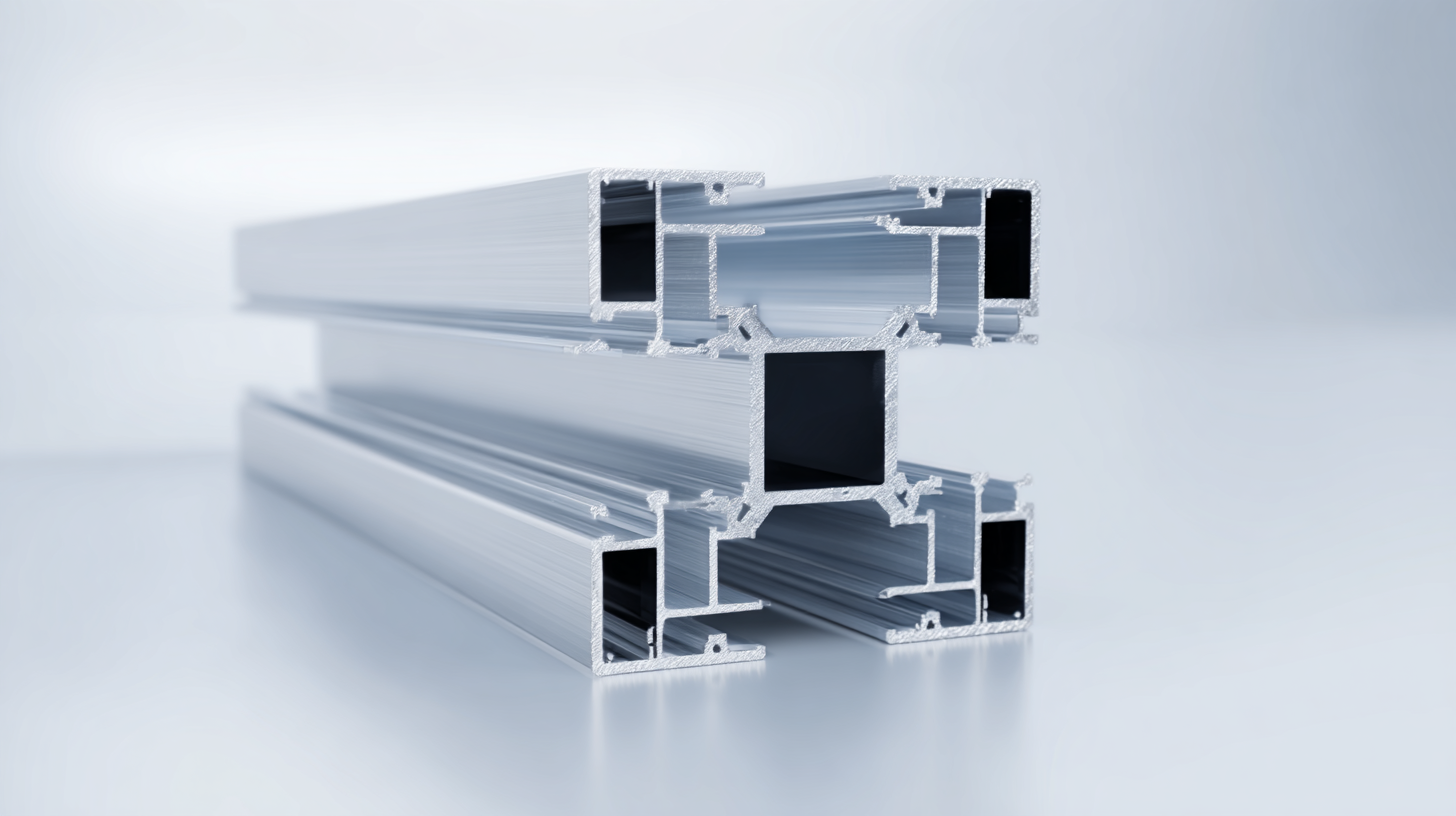

When selecting thermal break aluminium profiles for your project, it is essential to understand the various thermal break technologies available and their specific applications. Different thermal break methods, such as polyamide strips, polyurethane, and thermal bridge-free designs, offer distinct advantages in energy efficiency and insulation performance. For instance, studies have demonstrated that profiles with a polyamide thermal break can achieve a thermal transmittance of as low as 1.3 W/m²K, significantly enhancing a building's energy performance.

Tips: Consider the climate and intended use of your building when choosing the right profile. If your project is in a colder region, profiles utilizing polyurethane might offer superior insulation properties, supporting energy-efficient solutions.

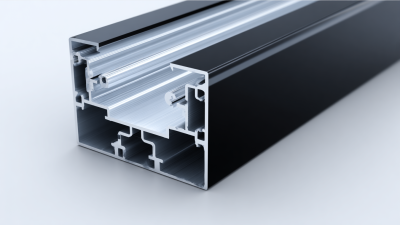

Moreover, as the demand for sustainable building materials rises, integrating thermal break technologies with bio-based insulation can further improve overall energy efficiency. These bio-based materials typically exhibit lower thermal conductivity and moisture buffering capacities, making them a fitting complement to aluminum profiles. With advancements in materials science, including nanofluids and their ability to enhance thermal management, professionals should stay informed about the latest technologies that can optimize energy performance in building applications.

Tips: Always verify the thermal performance ratings and certifications of the materials you intend to use to ensure compliance with local building codes and standards.

When considering thermal break aluminium profiles for your project, a crucial aspect is the long-term financial impact. While high-quality thermal breaks may come with a higher initial cost, their potential for substantial energy savings should not be overlooked. These profiles improve insulation, reducing the amount of energy required for heating and cooling, which can lead to lower utility bills over time.

Additionally, investing in quality thermal breaks often translates into enhanced durability and reduced maintenance costs. Superior products are designed to withstand environmental stressors, minimizing the need for repairs or replacements. A cost-benefit analysis should therefore factor in both the immediate investment and the anticipated savings over the lifespan of the materials. Ultimately, choosing the right thermal break solution not only enhances energy efficiency but also contributes to the overall financial viability of the project in the long run.

| Profile Type | Initial Cost ($/m) | Installation Cost ($/m) | Average Lifespan (Years) | Energy Savings ($/year) | Total Cost Over Lifespan ($) | Net Savings ($) |

|---|---|---|---|---|---|---|

| Standard Profile | 50 | 20 | 30 | 200 | 2100 | -1090 |

| Premium Profile | 80 | 25 | 40 | 350 | 5300 | +1820 |

| Eco-Friendly Profile | 70 | 30 | 35 | 300 | 6200 | +2800 |