In the realm of sustainable construction, the utilization of Broken Bridge Aluminium Profiles has emerged as a pivotal factor in enhancing energy efficiency.

According to a report by the International Energy Agency, buildings account for approximately 30% of global energy consumption, underscoring the importance of integrating energy-efficient materials and designs to mitigate environmental impact.

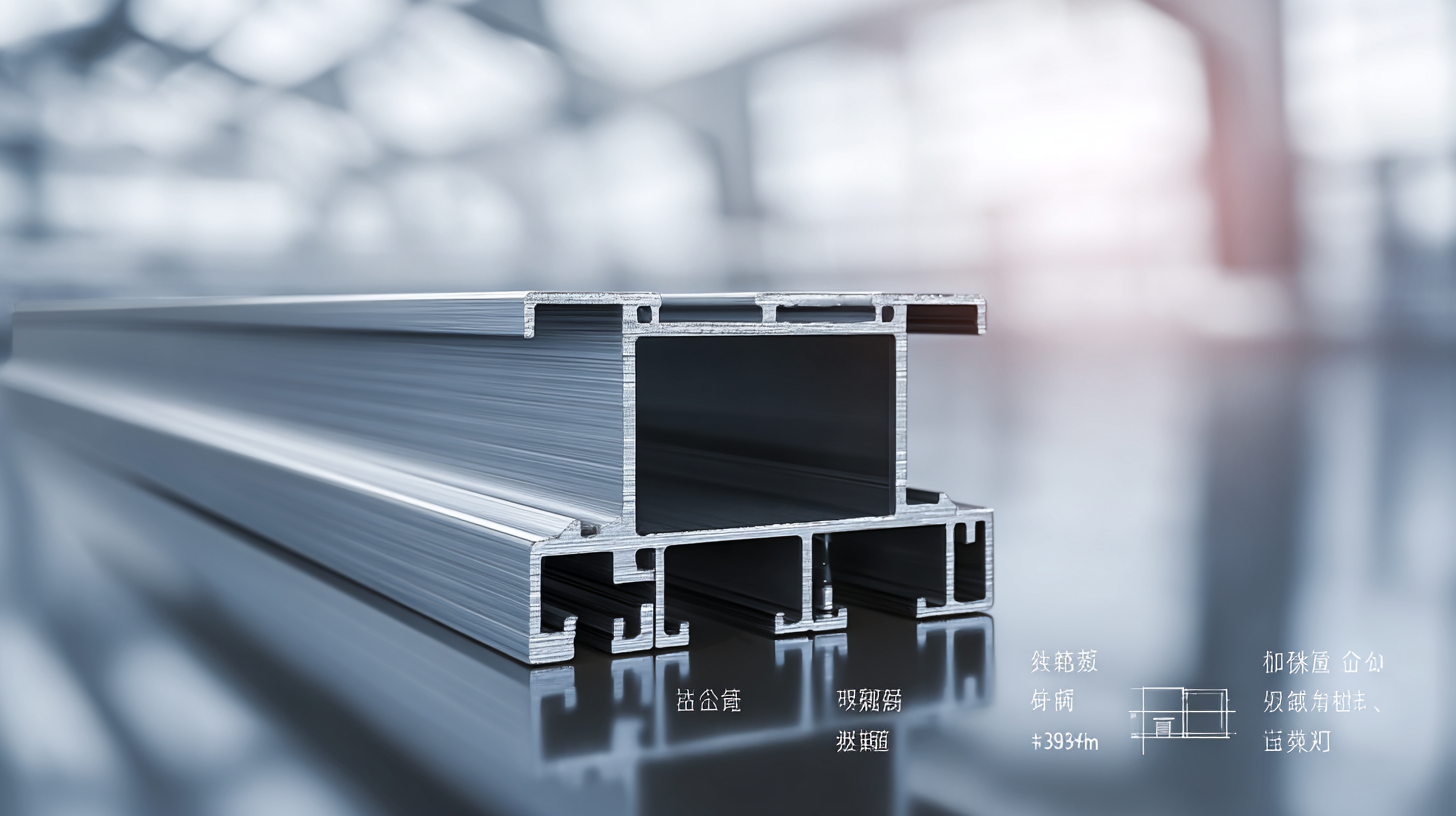

Broken Bridge Aluminium Profiles, known for their superior thermal insulation properties, play a crucial role in minimizing energy loss within buildings. These innovative profiles not only offer exceptional durability but also provide significant long-term savings in maintenance and repair costs, as highlighted in a study by the Aluminum Association, which noted that the lifecycle cost savings can exceed 20% when using energy-efficient materials.

By unlocking the potential of these profiles, construction professionals can contribute to sustainable practices while meeting the growing demand for energy-efficient buildings.

Broken Bridge Aluminium Profiles, known for their superior thermal insulation properties, play a crucial role in minimizing energy loss within buildings. These innovative profiles not only offer exceptional durability but also provide significant long-term savings in maintenance and repair costs, as highlighted in a study by the Aluminum Association, which noted that the lifecycle cost savings can exceed 20% when using energy-efficient materials.

By unlocking the potential of these profiles, construction professionals can contribute to sustainable practices while meeting the growing demand for energy-efficient buildings.

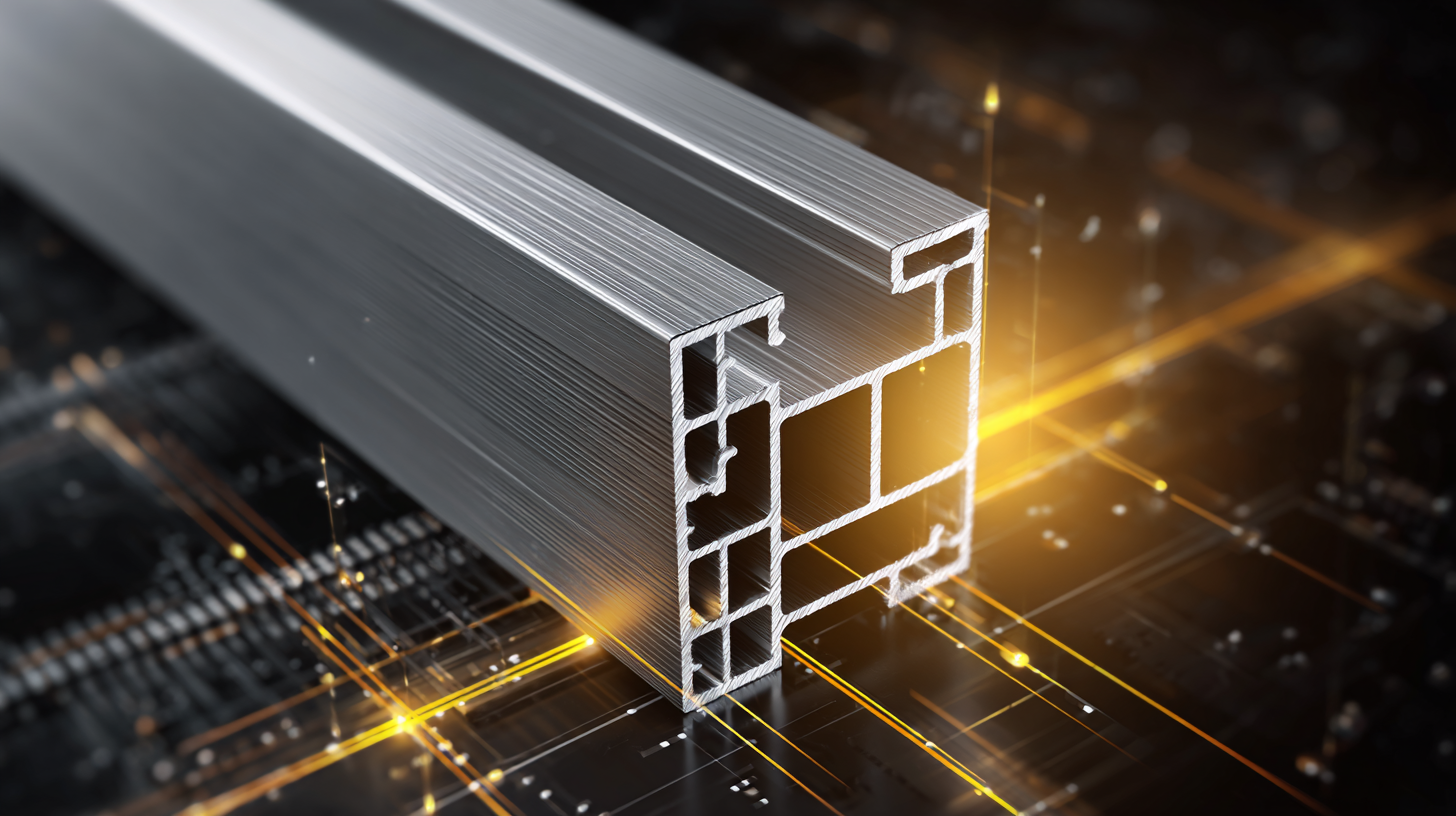

In the realm of sustainable construction, broken bridge aluminium profiles play a pivotal role in enhancing energy efficiency in building design. These innovative profiles feature a thermal break, which significantly reduces heat transfer between the interior and exterior environments. This characteristic is crucial for modern energy-efficient buildings, as it helps maintain a comfortable indoor climate while minimizing energy consumption for heating and cooling. With the growing emphasis on sustainability, architects and builders are increasingly turning to broken bridge aluminium profiles to meet stringent energy regulations and improve overall building performance.

Moreover, the versatility of broken bridge aluminium profiles allows for various design applications while ensuring high thermal insulation. They can be utilized in windows, doors, and curtain walls, providing not only aesthetic appeal but also functional superiority. This adaptability is essential in creating energy-efficient structures that stand the test of time. By incorporating these profiles into building designs, architects can facilitate better energy management strategies, ultimately contributing to reduced carbon footprints and promoting eco-friendly construction practices.

Broken bridge aluminium profiles have emerged as a game-changer in sustainable construction due to their exceptional thermal insulation properties. Unlike traditional aluminium, which conducts heat efficiently, broken bridge profiles feature a thermal break that significantly reduces heat transfer. This means buildings constructed with these profiles can maintain comfortable indoor temperatures while lowering heating and cooling costs. By enhancing energy efficiency, broken bridge profiles not only benefit homeowners with reduced utility bills but also contribute to a larger goal of minimizing overall energy consumption in construction.

Moreover, the durability and low maintenance requirements of broken bridge aluminium profiles further underscore their advantages in sustainable projects. These profiles are resistant to corrosion, ensuring a longer lifespan compared to other materials. This longevity translates into less frequent replacements and repairs, effectively reducing waste generated throughout the building’s lifetime. Additionally, their lightweight nature simplifies transportation and installation, which can lower the carbon footprint associated with construction activities. As the construction industry increasingly prioritizes sustainability, broken bridge aluminium profiles stand out as an essential component in achieving both energy efficiency and environmental responsibility.

| Dimension | Description | Benefits | Sustainability Impact |

|---|---|---|---|

| Thermal Insulation | Prevention of heat transfer | Reduced energy consumption | Lower carbon footprint |

| Durability | Resistant to corrosion and weathering | Longer lifespan of structures | Minimized waste and resource use |

| Lightweight | Easier handling and installation | Cost-effective transportation | Reduces energy use in construction |

| Recyclability | 100% recyclable materials | Promotes circular economy | Less environmental impact |

| Aesthetic Flexibility | Variety of finishes and designs | Enhances architectural appeal | Supports modern and sustainable design |

Broken bridge aluminium profiles have emerged as a crucial component in sustainable construction, particularly when it comes to enhancing thermal insulation and achieving significant energy savings. These profiles are designed with a thermal break—an insulating strip made of non-conductive materials—effectively minimizing heat transfer between the interior and exterior environments. This feature is essential for reducing the energy required for heating and cooling, leading to lower energy bills and a reduced carbon footprint.

Broken bridge aluminium profiles have emerged as a crucial component in sustainable construction, particularly when it comes to enhancing thermal insulation and achieving significant energy savings. These profiles are designed with a thermal break—an insulating strip made of non-conductive materials—effectively minimizing heat transfer between the interior and exterior environments. This feature is essential for reducing the energy required for heating and cooling, leading to lower energy bills and a reduced carbon footprint.

Moreover, the use of broken bridge aluminium profiles contributes to comfort within living and working spaces. By maintaining a steadier indoor temperature and minimizing drafts, these profiles help create a more pleasant environment for occupants. The enhanced thermal performance provided by these profiles also extends the lifespan of heating and cooling systems, as they work more efficiently. As the demand for energy-efficient building solutions continues to rise, integrating broken bridge aluminium profiles into architectural designs proves to be a strategic investment in both sustainability and long-term savings.

The world is increasingly pivoting towards sustainable construction practices, and the role of advanced manufacturing technologies in producing high-quality broken bridge aluminium profiles is paramount. These profiles are essential for energy-efficient buildings, offering superior thermal insulation and structural integrity. With innovations in manufacturing processes, manufacturers can achieve precise tolerances and enhanced material properties, allowing for a reduction in energy consumption and greenhouse gas emissions in the long run.

Advanced manufacturing techniques, such as automated extrusion and advanced coatings, not only improve the durability and aesthetic appeal of aluminium profiles but also contribute to their environmental performance. By utilizing recycled materials and minimizing waste during production, companies can create profiles that are both cost-effective and environmentally friendly. As the demand for green buildings rises, the impact of these innovations will be instrumental in transforming the construction industry, ensuring that materials are sustainable, efficient, and aligned with the principles of eco-friendly design.

The global aluminium industry is poised for transformative change, particularly with China taking a leading role in sustainable production practices. Recent developments indicate a shift towards "green aluminium," which not only meets rising global demand but also addresses pressing environmental concerns. As companies adopt more sustainable measures, the emphasis on recycling and reducing carbon emissions becomes paramount. This push aligns with global trends where the aluminium market is anticipated to grow significantly, reflecting increasing consumer and regulatory pressures for greener practices.

Moreover, cooperatives around the world, such as those in Việt Nam, are embracing a green transformation to enhance their brand image and foster competitiveness in the international arena. By prioritizing clean production processes, these cooperatives not only meet the sustainability criteria set by global markets but also promote the economic advantages of recycled metals. The recycled metal market is projected to expand, indicating a robust future for sustainable materials, especially in aluminium production. As the industry evolves, businesses that capitalize on eco-friendly practices are likely to thrive, contributing to a more sustainable construction landscape.