In today's global sourcing landscape, the demand for high-quality materials continues to rise, particularly for products like Aluminum Handle Extrusions. According to a report by the Global Aluminum Extrusions Market, the value of aluminum extrusions is expected to reach USD 90 billion by 2024, growing at a CAGR of 6.5%. This growth is driven by the increasing applications in various industries, including automotive, construction, and consumer goods. The superior strength-to-weight ratio, corrosion resistance, and versatility of aluminum make it an ideal choice for handle extrusions, which play a critical role in product aesthetics and functionality. As businesses navigate the complexities of international trade and compliance, understanding the essential reasons to choose the best aluminum handle extrusions becomes pivotal. This blog delves into seven key advantages that highlight why sourcing high-quality aluminum handle extrusions can be a game-changer for companies aiming to enhance their product offerings while ensuring operational efficiency.

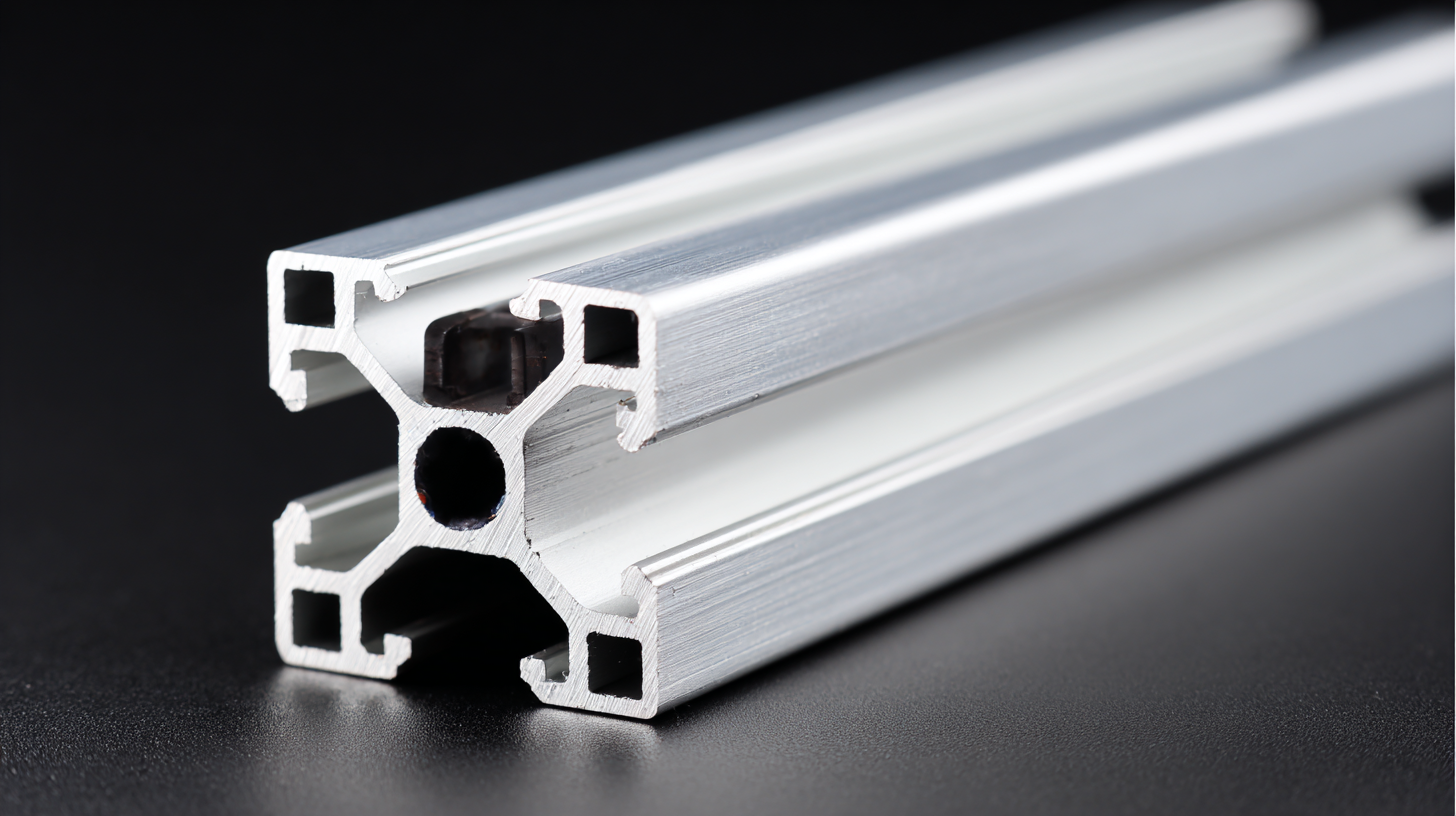

When it comes to global sourcing strategies, aluminum handle extrusions stand out for their unique advantages. These lightweight yet durable materials are perfect for a variety of applications, making them highly sought after in diverse industries. The strength-to-weight ratio of aluminum ensures that products remain sturdy without adding unnecessary bulk, which is crucial in today’s competitive market where efficiency and cost-effectiveness are paramount.

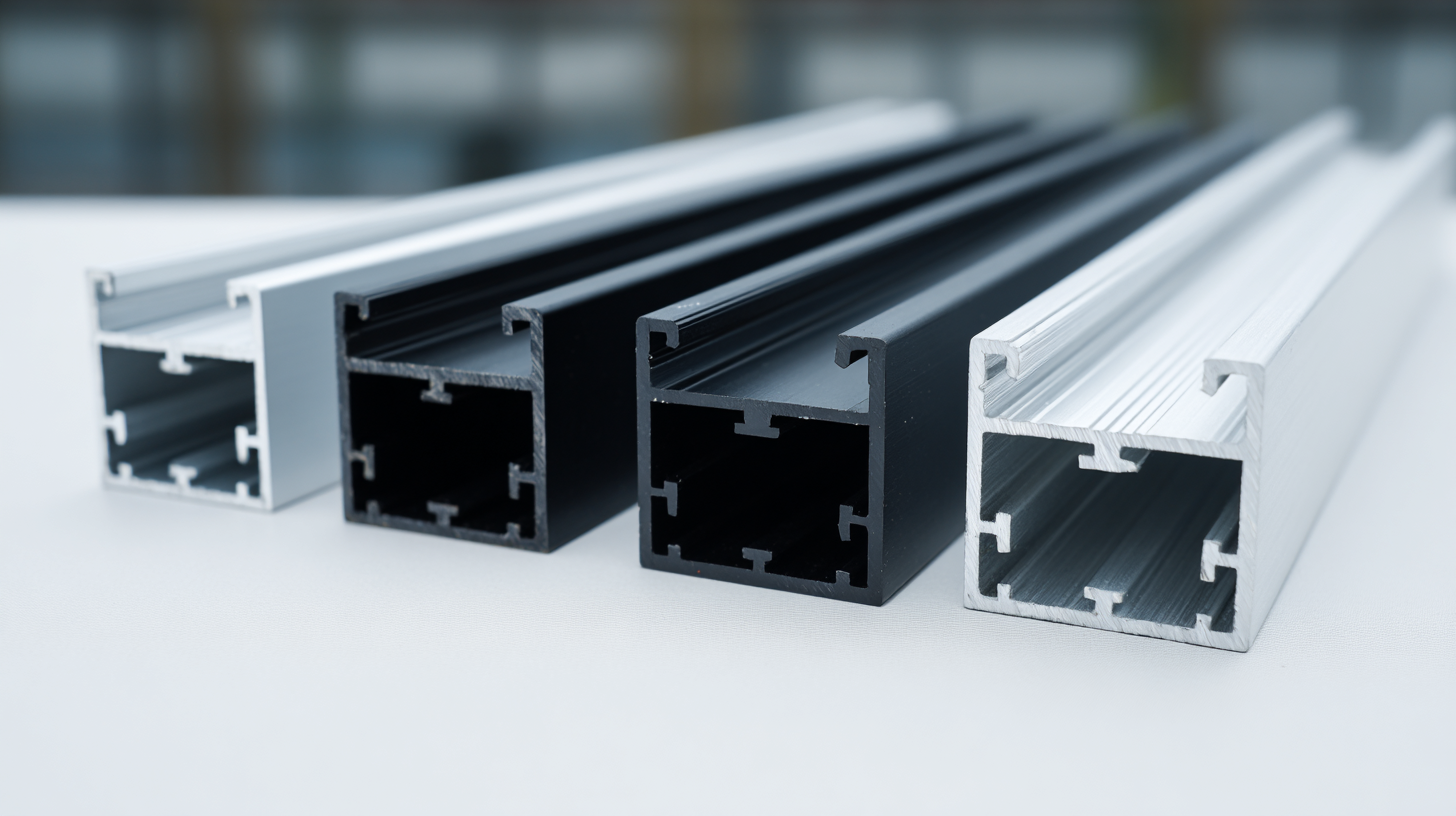

One important tip when considering aluminum handle extrusions is to evaluate the specific requirements of your project. Different applications may require varying thicknesses and finishes, so understanding the desired performance will help in selecting the optimal type of extrusion. Additionally, seeking suppliers that offer customizable solutions can help tailor the materials to meet precise specifications, ensuring that you get the best value for your investment.

Another consideration is the environmental benefits of aluminum. It is a sustainable material that can be recycled multiple times without losing its properties. Incorporating aluminum handle extrusions into your sourcing strategy can not only enhance your product offerings but also align with eco-friendly practices, appealing to a growing market that values sustainability.

| Advantage | Description | Impact on Sourcing |

|---|---|---|

| Lightweight | Aluminum handle extrusions are significantly lighter than other materials, making shipping cost-effective. | Reduced shipping costs lead to lower overall sourcing expenses. |

| Corrosion Resistance | Aluminum does not rust and withstands various environmental conditions. | Increased product longevity minimizes replacement needs. |

| Customization | Aluminum extrusions can be easily customized to meet specific design requirements. | Enhanced product designs attract more customers. |

| Recyclability | Aluminum is 100% recyclable, promoting sustainability. | Aligns with global sustainability goals, appealing to eco-conscious consumers. |

| Strength | Aluminum offers high strength-to-weight ratio, ensuring durability. | Durable products lead to customer satisfaction and repeat business. |

| Cost-effective | Aluminum is relatively inexpensive compared to other metals. | Lower material costs improve profit margins. |

| Aesthetic Appeal | Aluminum can be anodized or powder-coated, enhancing appearance. | Attractive products increase consumer interest and sales. |

When it comes to sourcing materials for manufacturing, cost-efficiency is a critical factor that can significantly impact the bottom line. Aluminum handle extrusions stand out as a prime choice for businesses looking to streamline their production processes while minimizing expenses. The lightweight nature of aluminum not only reduces shipping costs but also allows for easier handling during assembly. This advantage can lead to substantial savings in both labor and transportation expenses, making aluminum extrusions an ideal choice for global sourcing.

Moreover, aluminum extrusions offer high durability and resistance to corrosion, which translates into lower maintenance costs over time. Manufacturers can enjoy a longer lifespan for their products, reducing the need for frequent replacements and repairs. By investing in aluminum handle extrusions, companies can optimize their production efficiency and deliver quality products without compromising their budget. Embracing these cost-effective materials is a smart strategy for businesses aiming for sustainability and profitability in an increasingly competitive global market.

When considering materials for manufacturing, the durability and strength of aluminum handles make them an outstanding choice. Aluminum is inherently resistant to corrosion, which means that handles made from this material can withstand exposure to harsh environments without degrading. This quality not only ensures a longer lifespan but also reduces the frequency of replacements, ultimately saving manufacturers both time and money in the long run.

Moreover, aluminum handles provide a unique blend of lightweight and robust characteristics. They offer excellent mechanical strength while remaining easy to handle, making them ideal for a variety of applications. This combination allows for more versatile design possibilities, enabling manufacturers to create ergonomic products that enhance user experience. By investing in aluminum handle extrusions, companies can meet the needs of global sourcing while ensuring that they deliver high-quality, durable products to consumers.

When it comes to global sourcing, the flexibility offered by aluminum extrusions plays a pivotal role in meeting diverse design needs. The ability to customize aluminum profiles allows manufacturers to tailor products specifically for their applications, whether for lightweight structures or intricate designs. This adaptability opens the door for innovation, enabling companies to explore new functionalities that align with evolving market trends.

The recent trends in various industries highlight the importance of customization in product development. For instance, advances in modular designs, like those seen in the modular plastic chain conveyor market, showcase the trend towards more adaptable and user-friendly solutions. Similarly, the aluminum alloy extrusion profiles market is set to grow significantly, reflecting the increasing demand for customizable components that meet specific performance criteria. As industries continue to seek solutions that balance functionality with aesthetic appeal, aluminum extrusions will undoubtedly remain a cornerstone for businesses looking to foster creativity and efficiency in their sourcing strategies.

The eco-friendly aspects of using aluminum in manufacturing are increasingly drawing attention from businesses looking to enhance their sustainability practices. Aluminum is one of the most recyclable materials available, with a recycling rate of over 75%. This means that products made from aluminum can be melted down and reused indefinitely, significantly reducing the need for new raw materials and the energy consumption associated with their extraction and processing. By choosing aluminum handle extrusions, companies can align their sourcing strategies with environmentally responsible practices, thereby minimizing their carbon footprint.

Moreover, aluminum production is becoming greener as innovations in manufacturing processes emerge. Advances in technology have led to more energy-efficient methods and reduced greenhouse gas emissions during the production phase. Companies opting for aluminum not only benefit from its lightweight and durable nature but also contribute to a circular economy where resources are kept in use for as long as possible. As consumer demand for sustainable products rises, integrating aluminum into manufacturing processes not only meets regulatory requirements but also enhances brand reputation, appealing to environmentally conscious consumers.