In the ever-evolving landscape of the manufacturing industry, the process of "Building Aluminium Profiles" has become increasingly significant. As emphasized by industry expert Dr. Michael Reynolds, renowned for his contributions to aluminium fabrication, "Efficiency in building aluminium profiles not only reduces costs but also enhances the overall quality of the final product." This statement echoes the urgency for manufacturers to adopt best practices that streamline their operations while maintaining high standards.

To navigate the complexities associated with Building Aluminium Profiles, it is essential to understand the intrinsic factors that contribute to both efficiency and effectiveness. The balance between innovation and traditional techniques plays a crucial role in optimizing production processes. Furthermore, as the demand for customised aluminium profiles rises, manufacturers must be equipped with not only the right tools but also the strategic insights that can propel their operations forward.

This article outlines ten essential tips designed to enhance efficiency in the process of Building Aluminium Profiles. By integrating these strategies into daily practices, companies can achieve significant improvements, ultimately contributing to their sustainability and success in a competitive market.

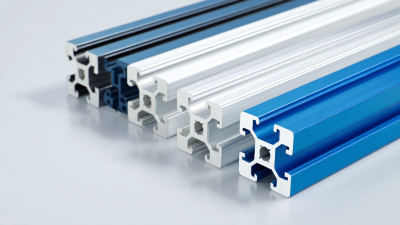

Aluminium profiles have become a cornerstone in various industries, from construction to aerospace, due to their lightweight nature and high strength. Understanding the basics of aluminium profile construction is crucial for those looking to maximize efficiency in manufacturing. According to a recent report by the Aluminium Association, the demand for aluminium profiles is expected to grow by 5.5% annually, driven largely by innovations in building techniques and designs that leverage the unique properties of aluminium. This growth emphasizes the necessity for manufacturers to comprehend fundamental construction principles to optimize production processes.

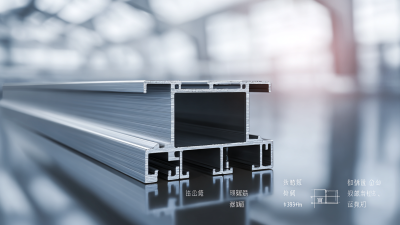

At the core of aluminium profile construction is the extrusion process, where aluminium is forced through a shaped die to create profiles of varying cross-sections. This technique not only allows for complexity in design but also enhances material savings, as it minimizes waste—a significant advantage as highlighted in a 2022 study by the International Aluminium Institute, which stated that efficient profile design could reduce material consumption by up to 30%. By embracing these fundamentals, manufacturers can streamline operations, reduce costs, and meet the rising demand for complex, tailor-made aluminium solutions that cater to specific industrial needs.

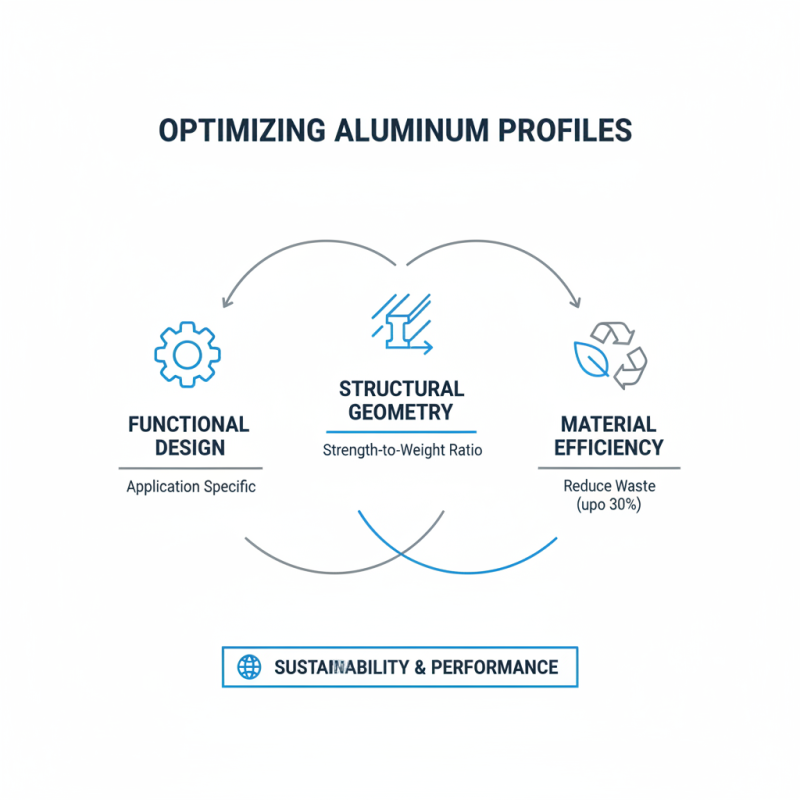

When designing aluminium profiles, several key factors can significantly influence both their efficiency and overall performance. One of the most critical elements is the design itself, which must consider both the functional and structural requirements of the application. According to the Aluminium Association, optimally designed profiles can reduce material waste by up to 30%, a significant saving that also contributes to environmental sustainability. This means that thoughtful consideration of geometry and cross-sectional shape is essential for maximizing strength while minimizing weight.

Another important factor is the choice of manufacturing techniques, such as extrusion, which plays a pivotal role in the efficiency of aluminium profiles. Recent studies indicate that advancements in extrusion technology can enhance production speeds by 20% while improving the uniformity and precision of the profiles produced. Furthermore, the cooling and aging processes also dictate the mechanical properties of the final product. A report from the International Aluminium Institute reveals that optimally managing these processes can lead to a 15% increase in yield strength, thus ensuring that the profiles meet the necessary performance standards for their intended use. By focusing on these factors, manufacturers can build aluminium profiles that not only meet but exceed industry standards for efficiency and effectiveness.

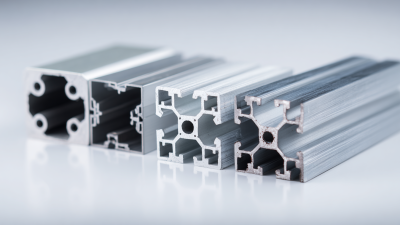

When embarking on the journey of building aluminium profiles, having the right tools and equipment is crucial for efficiency and precision. According to a report from the International Aluminium Institute, the global aluminium demand is forecasted to grow by 5% annually over the next decade, underscoring the importance of optimizing production processes in this competitive industry. Essential tools such as high-precision cutting machines and CNC milling devices play a crucial role in achieving high-quality finishes while minimizing waste. The adoption of automated cutting technologies alone can enhance productivity by up to 30%, making it an indispensable component of modern aluminium fabrication.

In addition to cutting equipment, investing in advanced measuring tools is vital to ensure that aluminium profiles meet stringent quality standards. Laser measuring systems, for instance, can achieve accuracies of ±0.1 mm, which significantly reduces the risk of defects in the final product. Furthermore, leveraging software solutions designed for CAD (Computer-Aided Design) can streamline the design-to-production workflow, allowing for quicker adjustments and iterations. Research indicates that effective integration of these technologies not only improves operational efficiency but can also lead to cost savings of up to 20% in the overall manufacturing process. By equipping production lines with these essential tools, manufacturers can not only meet growing market demands but also enhance their overall competitiveness.

Quality control in aluminium profile production is essential for ensuring the longevity and performance of the final products. One of the best practices includes implementing strict inspection protocols at each stage of the manufacturing process. This starts with raw material assessment, where the purity and quality of the aluminium must be verified before it is transformed into profiles. Regular checks during extrusion, cutting, and finishing processes further ensure that any defects are identified and addressed promptly, reducing waste and rework costs.

Another important aspect of quality control is the use of advanced technology and machinery to enhance precision. Utilizing automated systems for measurements can significantly minimize human error and improve consistency. Additionally, conducting regular maintenance on machinery ensures that equipment operates at optimal levels, contributing to the production of high-quality aluminium profiles. Training workers in quality awareness and inspection techniques also plays a significant role, as it empowers the workforce to take ownership of the quality of their output, fostering a culture of excellence throughout the production line.

In the aluminium profile manufacturing sector, efficiency is paramount for maintaining competitiveness. According to a report by Smithers Pira, the global aluminium extrusion market is projected to reach $60 billion by 2025, highlighting the importance of adopting innovative manufacturing techniques to optimize production processes. One effective approach involves the integration of advanced automation technologies, which can significantly reduce cycle times and labor costs. Companies leveraging robotics in their production lines have seen productivity increases of up to 30%, while also enhancing precision in cutting and assembly processes.

Another essential method is the implementation of real-time data analytics. By utilizing IoT-enabled machines, manufacturers can gather critical performance metrics and gain insights into operational efficiency. A study by the International Aluminium Institute indicates that factories utilizing predictive maintenance techniques could reduce their downtime by up to 50%, leading to substantial cost savings and improved output. Moreover, embracing additive manufacturing technologies for prototyping can streamline design processes and allow for more complex geometries in profiles, thereby expanding the product offerings available to customers. These innovative techniques not only bolster production efficiency but also enhance product quality, catering to the growing demand for customized aluminium profiles in various industries.

| Tip No. | Technique | Description | Key Benefit |

|---|---|---|---|

| 1 | Material Selection | Choose the right alloy for specific applications to enhance strength and corrosion resistance. | Improved durability and performance. |

| 2 | Process Optimization | Streamline fabrication processes to minimize waste and reduce cycle times. | Cost savings and faster delivery. |

| 3 | Quality Control | Implement rigorous testing and inspection standards throughout the manufacturing process. | Enhanced product reliability and customer satisfaction. |

| 4 | Use of Automation | Integrate automated systems for cutting, welding, and finishing. | Increased efficiency and precision. |

| 5 | Advanced Software | Utilize CAD and CAM software to enhance design accuracy and production planning. | Streamlined design-to-production workflow. |

| 6 | Training and Development | Invest in employee training programs to enhance skills and knowledge on new techniques. | A more skilled workforce leading to higher quality outputs. |

| 7 | Prototyping | Create prototypes to test designs before full-scale production. | Reduced risk of errors and design flaws. |

| 8 | Sustainable Practices | Implement recycling and waste management processes in manufacturing. | Cost efficiencies and environmentally friendly operations. |

| 9 | Collaboration | Work closely with suppliers and customers for feedback and improvement. | Stronger relationships and refined products. |

| 10 | Regular Maintenance | Schedule regular maintenance for equipment to ensure optimal performance. | Minimized downtime and increased productivity. |