In today's fast-paced construction and manufacturing industries, the demand for efficient and reliable materials has never been greater. One such material that is gaining traction is Insulated Aluminium Extrusion, known for its outstanding thermal performance and versatility. As projects increasingly prioritize energy efficiency and sustainability, selecting the right insulated aluminium extrusion becomes crucial. This blog will delve into the intricacies of choosing the best options for your unique requirements, addressing key factors such as insulation properties, durability, and aesthetic versatility. By mastering the art of selecting insulated aluminium extrusions, you not only enhance the functional aspects of your project but also contribute to a more sustainable future. Join us as we explore the future of insulated aluminium extrusions and their impact on modern design and construction.

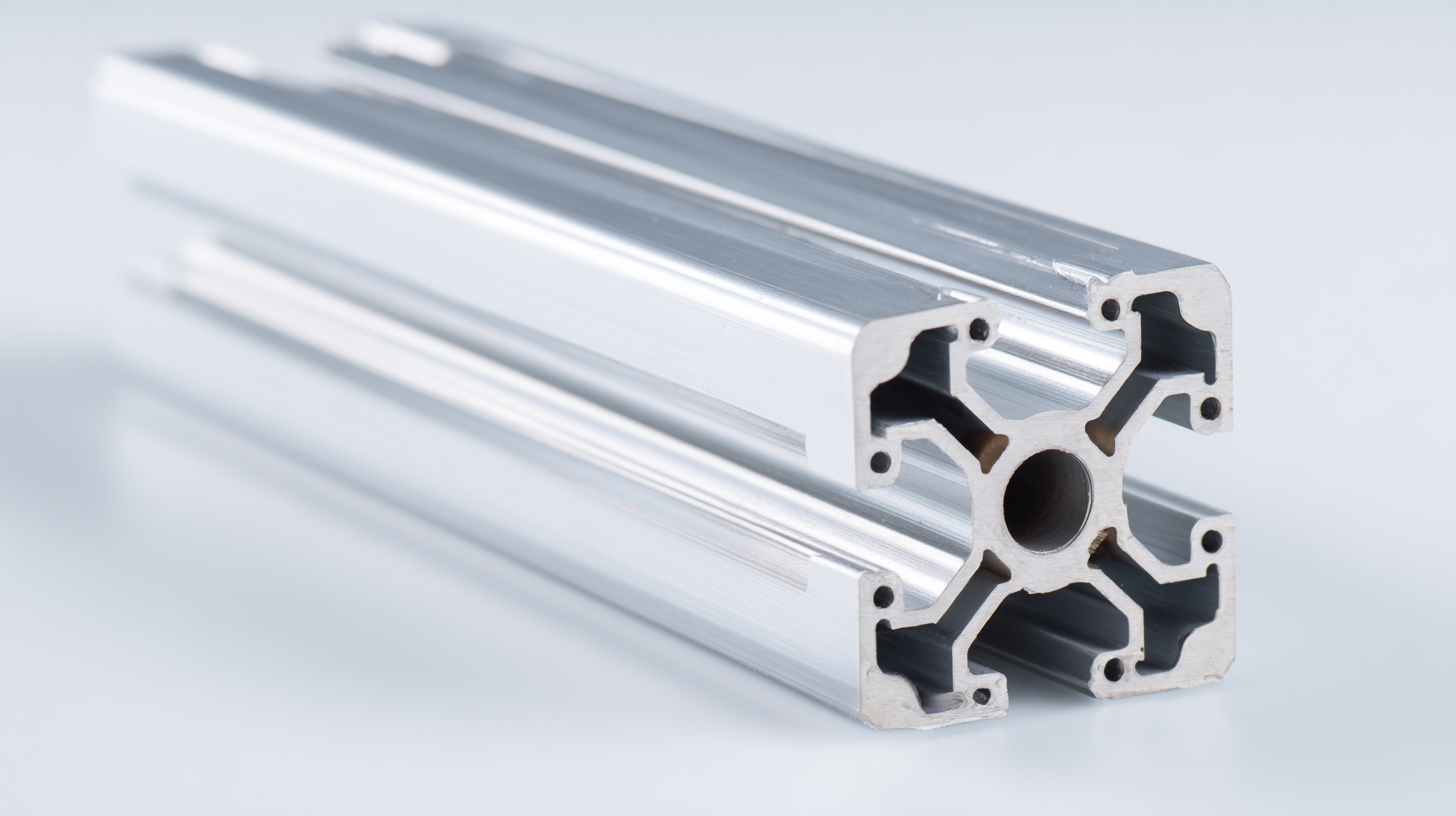

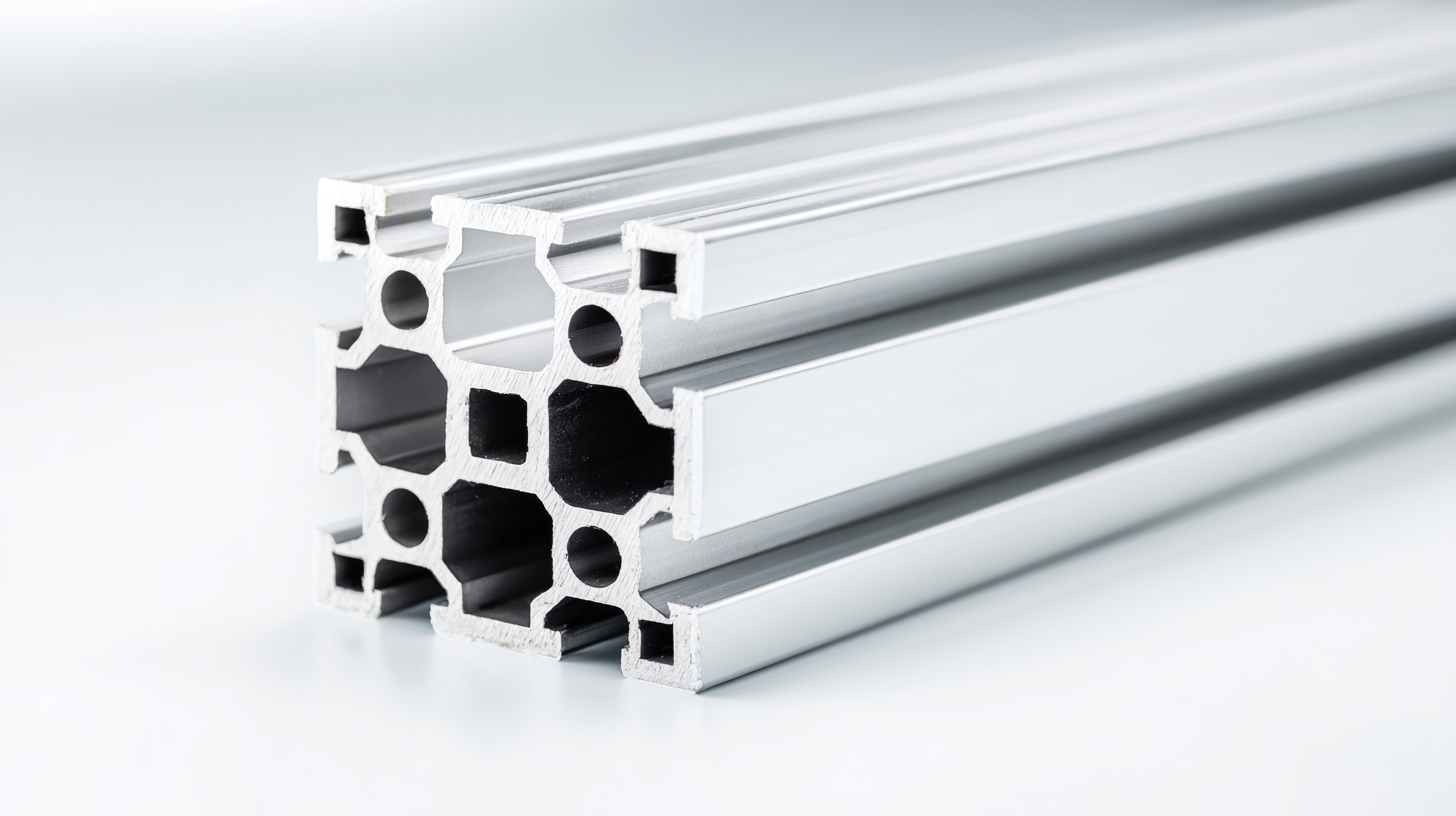

When embarking on a project that requires insulated aluminium extrusions, it's essential to understand their key features and benefits. Insulated aluminium extrusions combine the strength and versatility of aluminium with unique thermal insulation properties. This duality not only enhances energy efficiency but also contributes to improved acoustic performance. For applications like windows, doors, and curtain walls, insulated aluminium extrusions are an excellent choice, ensuring both durability and comfort.

Tip: When selecting insulated aluminium extrusions, ensure that the insulation material used provides an optimal thermal barrier. Look for products that meet or exceed energy efficiency ratings relevant to your region. Additionally, consider the thickness and composition of the aluminium for enhanced structural integrity.

Another significant advantage of insulated aluminium extrusions is their resistance to weathering and corrosion. This quality ensures longevity even in challenging environments, making them a cost-effective option over time. The design flexibility offered by aluminium also allows architects and builders to achieve modern aesthetics without compromising performance.

Tip: Always check the manufacturer's specifications for weather resistance and maintenance recommendations to ensure you choose an extrusion that fits your project's needs. Look for products that offer warranties, as this can be indicative of the quality and durability you can expect.

When selecting insulated aluminium extrusions for your projects, several critical factors should guide your decision-making process. First and foremost, it’s essential to consider the thermal performance of the extrusion. Look for products with a high thermal break to minimize heat transfer, which can lead to energy savings and improve comfort levels within a space. Additionally, the insulation material used is vital; options such as polyurethane or polystyrene offer varying levels of thermal resistance, so evaluating your specific needs is crucial.

Another significant factor is the extrusion's structural integrity and durability. You want to ensure that the material can withstand environmental stresses, particularly if it will be exposed to harsh weather conditions. Consider the alloy grade; high-strength aluminium alloys often provide superior resistance to corrosion and deformation. Lastly, pay attention to the design flexibility of the extrusion, such as the ability to be easily customized for specific applications. This adaptability can lead to more efficient project implementation while maintaining aesthetic quality.

| Factor | Description | Importance Level |

|---|---|---|

| Thermal Performance | Evaluate the insulation effectiveness to maintain temperature control. | High |

| Material Quality | Assess the durability and corrosion resistance of the aluminum used. | High |

| Cost | Consider the overall project budget and cost-effectiveness. | Medium |

| Compliance with Standards | Ensure the product meets local building codes and industry regulations. | High |

| Design Flexibility | Check if the extrusion can accommodate diverse design requirements. | Medium |

| Lead Time | Evaluate the manufacturing and delivery timeline for the extrusions. | Medium |

Insulated aluminium extrusions have become increasingly vital in various industries due to their exceptional thermal performance and lightweight properties. In the construction sector, for example, these extrusions are revolutionizing building design by enabling more energy-efficient structures. Their insulation capabilities contribute to reduced energy consumption and enhance comfort levels in residential and commercial buildings. This alignment with sustainability trends highlights the importance of selecting the right insulated aluminium extrusions for achieving optimal energy performance.

In the automotive industry, insulated aluminium extrusions play a crucial role in enhancing vehicle safety and efficiency. They are extensively used in components such as bumper beams and crash boxes, which not only serve to protect occupants during collisions but also assist in weight reduction, contributing to better fuel economy. Furthermore, advances in the microalloying and particle strengthening of 6000 series aluminium alloys are propelling the creation of high-performance materials, tailored for new energy vehicles. This innovation ensures that manufacturers can meet the rigorous demands for both safety and sustainability while embracing the benefits of insulated aluminium technologies.

When it comes to selecting between standard and insulated aluminium extrusions for your projects, understanding the comparative advantages is essential. Standard aluminium extrusions offer excellent strength and rigidity but often lack effective thermal performance. Conversely, insulated aluminium extrusions are designed to minimize heat transfer, making them preferable for applications where energy efficiency is crucial. A recent study has highlighted that insulated options can reduce thermal bridging, which is vital for maintaining comfortable indoor environments and can lead to significant energy savings over time.

Tips: Consider the thermal requirements of your project and select insulated extrusions if energy efficiency and climate control are priorities. Remember to review the specifications based on relevant standards, as this ensures that the materials used will meet the demands of your specific application. Furthermore, be mindful of the heavier density and mechanical properties of both types; while insulated options may have lower tensile strength, their energy-saving benefits can outweigh this drawback in many scenarios.

In the context of lifecycle impacts, research indicates that while traditional materials may offer immediate benefits, insulated aluminium extrusions could present a more sustainable choice over the long term. The incorporation of these materials in building retrofits has been shown to significantly lower overall environmental footprint, a factor that many builders and architects are now prioritizing.

When sourcing insulated aluminium extrusions, it's essential to consider the latest trends and innovations in the industry. The growing demand for specialized materials and flexible manufacturing processes is shaping the way extrusions are produced and selected. For instance, advancements in equipment allow for a greater variety of profiles and more precise construction, ensuring that the end product meets specific project requirements. This flexibility not only enhances production efficiency but also facilitates the incorporation of features such as nutritional enhancements in related fields like kibble production.

Additionally, innovations in processing methods are enabling manufacturers to create insulated extrusions that maintain high performance while minimizing environmental impact. Techniques that prioritize gentler handling and reduced energy consumption help deliver products that align with contemporary sustainability goals. By staying informed on these developments and understanding how they can influence the properties of insulated aluminium extrusions, you can make more informed decisions when selecting materials for your projects.

Engaging with suppliers who prioritize cutting-edge technologies and product versatility will further ensure that you source the best options for your specific needs.