As the construction industry increasingly prioritizes energy efficiency and sustainability, the demand for innovative materials such as Thermal Break Aluminum Extrusion is surging. According to a recent market analysis, the global aluminum extrusion market is projected to reach USD 130 billion by 2025, with thermal break applications witnessing a significant uptick due to their superior thermal insulation properties.

This demand is driven not only by stringent energy regulations but also by the growing trend of green building practices. With technological advancements enhancing the performance characteristics of thermal break systems, stakeholders in the construction and manufacturing sectors are keenly interested in the technical specifications that set the best thermal break aluminum extrusions apart. Understanding these specifications is critical as they not only influence product performance but also underpin strategies for meeting future market demands and regulatory landscapes.

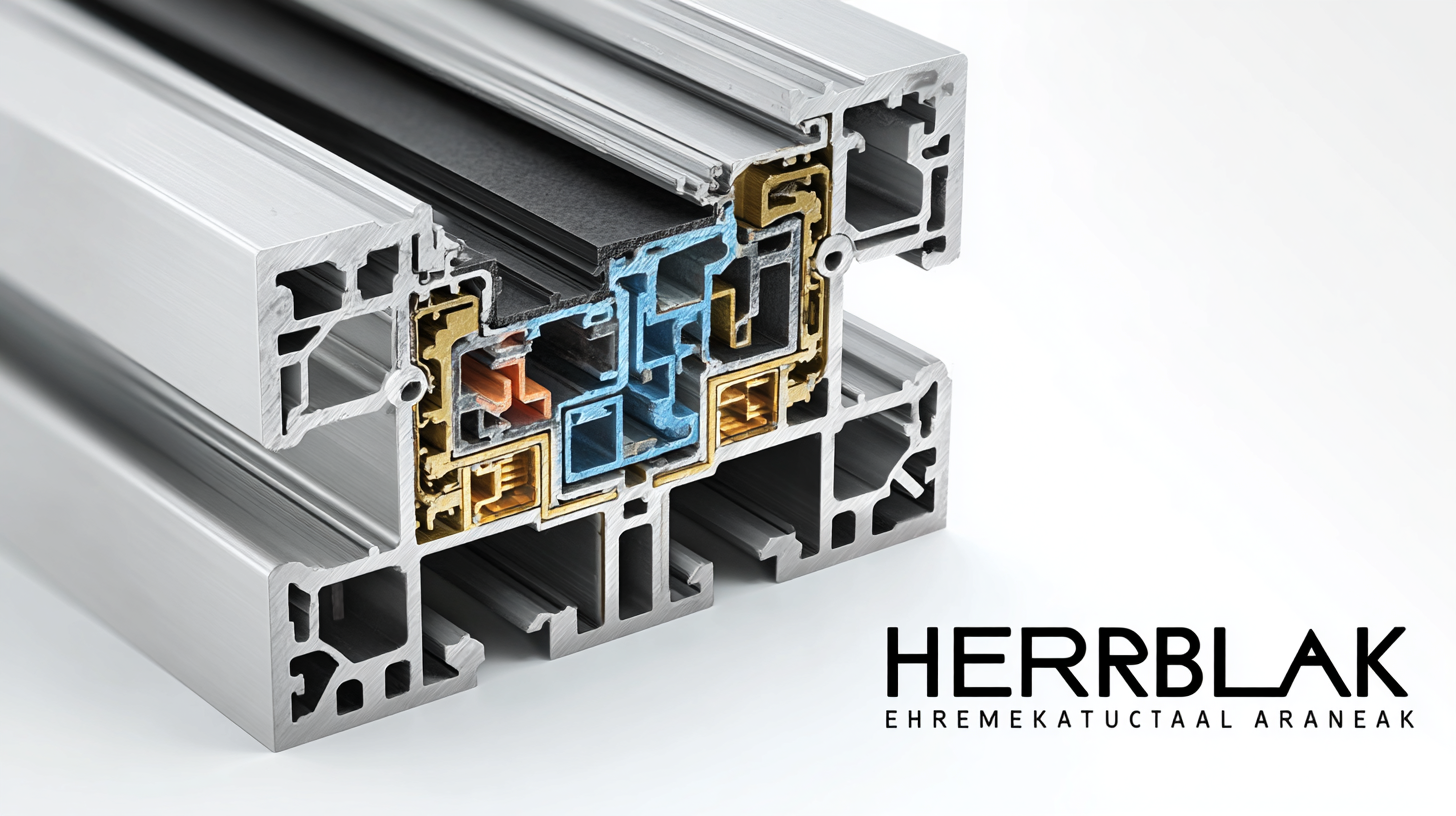

Thermal break technology plays a crucial role in enhancing the energy efficiency of aluminum extrusions, which are widely used in construction and architectural applications. By incorporating materials with lower thermal conductivity between the interior and exterior sections of an aluminum frame, thermal breaks significantly reduce heat transfer. According to industry reports, using thermal break aluminum extrusions can improve energy performance by up to 50% when compared to non-thermal break systems. This is particularly advantageous in regions with extreme temperatures, where energy costs can skyrocket due to heating and cooling needs.

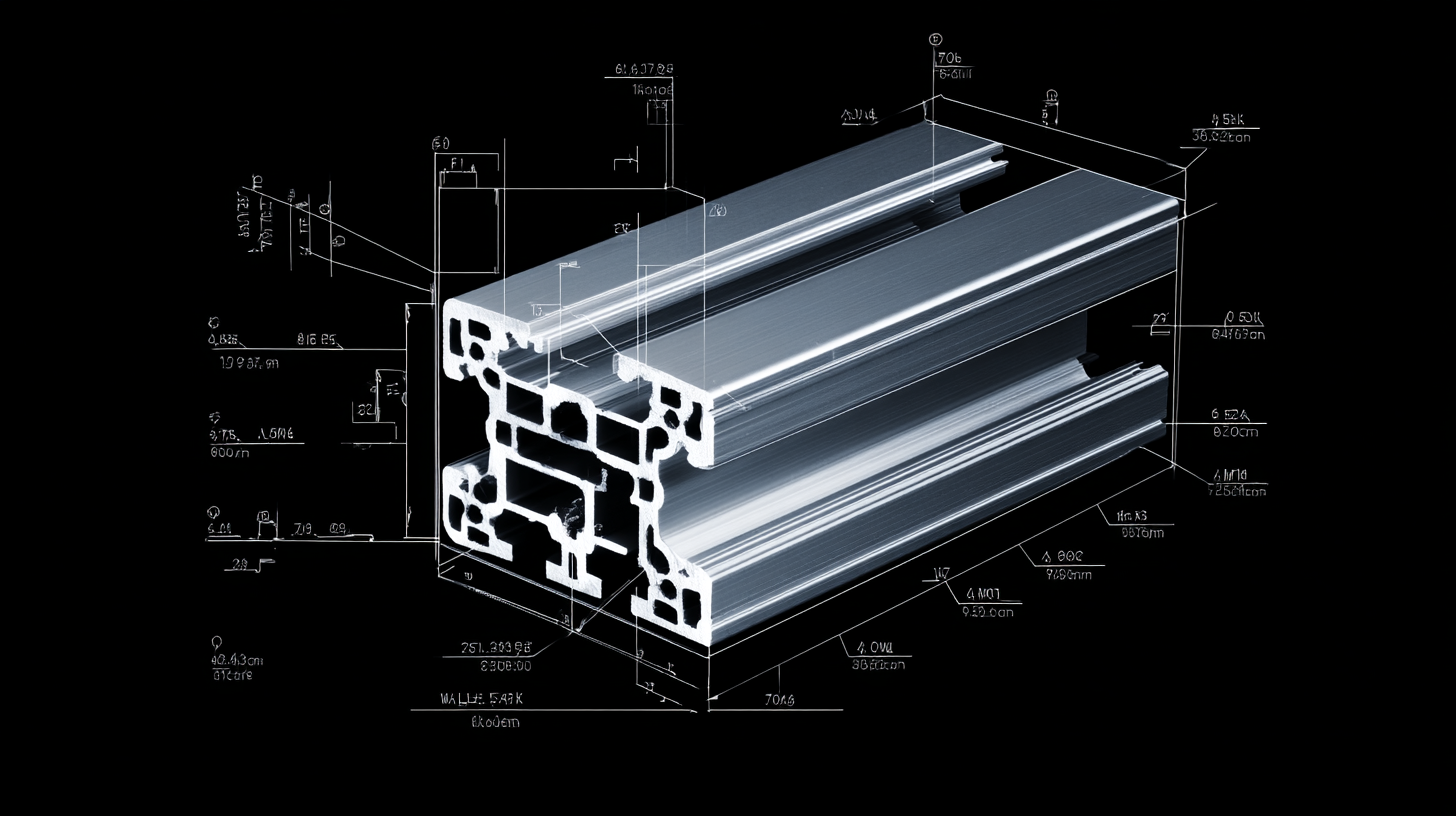

When considering thermal break options, it's essential to evaluate the insulation value, often represented as the Thermal Transmittance (U-value). Extrusions with a U-value of 0.17 W/m²K or lower are recommended for optimal energy efficiency. Additionally, ensure compliance with standards like the AAMA (American Architectural Manufacturers Association) guidelines, which provide benchmarks for performance.

Tip: Always look for third-party certifications that validate the performance claims of thermal break systems. This can save you time and ensure that your investment meets the required energy efficiency standards.

Tip: When specifying aluminum extrusions, consider the overall design and location of windows and doors; strategic placement can maximize the benefits of thermal break technology, leading to enhanced comfort and reduced energy bills.

Thermal break aluminum extrusions have gained popularity in construction and design due to their unique advantages over traditional materials. One primary benefit is their energy efficiency; the thermal break mechanism significantly reduces heat transfer, leading to lower energy costs and increased comfort in buildings. Unlike solid aluminum, which can conduct heat and cold, thermal break extrusions keep interior environments stable, making them an ideal choice for energy-efficient designs.

**Tip:** When selecting thermal break aluminum for your projects, look for high-performance thermal barriers that boast low U-values. This ensures maximum insulating properties, contributing to long-term energy savings.

Additionally, thermal break aluminum extrusions offer enhanced durability and resistance to weathering. They are less prone to condensation, which can lead to mold growth and damage over time. This resilience results in lower maintenance costs and a longer lifespan for windows, doors, and facades.

**Tip:** Consider anodized finishes for your extrusions, as they improve corrosion resistance and enhance the aesthetic appeal, providing both functional and visual benefits.

| Specification | Thermal Break Aluminum Extrusion | Alternatives |

|---|---|---|

| Thermal Conductivity | Low (0.1 - 0.2 W/m·K) | High (200 - 250 W/m·K) |

| Weight | Lightweight (2.7 g/cm³) | Heavy (Varies) |

| Energy Efficiency | High (up to 30% savings) | Lower (varies by material) |

| Corrosion Resistance | Excellent | Moderate |

| Installation Complexity | Easy | Potentially Complex |

| Lifespan | 50+ years | 10-30 years |

When considering aluminum extrusion profiles for construction, the choice between thermal break and non-thermal break profiles can significantly impact energy efficiency and performance. Thermal break profiles feature an insulating layer that minimizes heat transfer, making them ideal for buildings in varying climates. On the other hand, non-thermal break profiles may suffice for mild environments but can lead to higher energy costs over time due to increased thermal conductivity.

Tips: When selecting your profiles, evaluate the climate in which your structure will reside. If extreme temperatures are a concern, opting for thermal break profiles may prove cost-effective in the long run. Additionally, consider the sustainability of the materials used, as more efficient thermal profiles often reduce the overall carbon footprint of a building.

In a side-by-side comparison, thermal break profiles tend to excel in the areas of comfort and energy savings, while non-thermal options might be more affordable upfront. However, careful analysis reveals that the initial investment in thermal break systems is often justified through lower operational costs.

Tips: Always consult with a building professional to assess your specific needs and to ensure the chosen profile aligns with your long-term building goals. Understanding these distinctions can facilitate smarter investment decisions in your building projects.

As the demand for energy-efficient building materials grows, architects and builders are increasingly exploring innovative alternatives to traditional thermal break aluminum extrusions. These alternatives offer significant advantages in terms of thermal performance, weight, and overall sustainability. For instance, materials such as fiberglass and polyamide composites have emerged as viable substitutes, providing excellent insulation properties without compromising structural integrity. By integrating these materials into building designs, stakeholders can achieve a reduced energy footprint, leading to long-term cost savings on heating and cooling.

Moreover, advancements in technology have led to the development of hybrid systems that combine aluminum with advanced insulating materials. These systems utilize a unique design that incorporates thermally efficient materials while maintaining the aesthetic and mechanical benefits of aluminum. This not only enhances energy efficiency but also expands design opportunities, allowing for more versatile building envelopes. As the industry gravitates toward eco-friendliness, exploring such innovative alternatives becomes essential for meeting both design aspirations and environmental standards.

When selecting the right thermal break solution for your project, it's crucial to consider various factors that influence performance, aesthetics, and energy efficiency. Thermal break aluminum extrusions are designed to significantly reduce heat transfer between the interior and exterior of buildings, enhancing energy conservation and comfort. It's essential to assess the specifications of the aluminum profiles you plan to use, including their thermal performance, structural integrity, and environmental impact.

Understanding the specific needs of your project, such as climatic conditions and building design, will help guide your selection. High-performance thermal break systems often feature innovative designs that incorporate materials with low thermal conductivity, leading to better insulation values and reduced energy costs. Furthermore, the choice of finish and color can impact not only the visual appeal of your project but also its overall durability and maintenance requirements. By evaluating these criteria, you can ensure that your thermal break solution meets the unique demands of your project.